Good inventory management software is always a highly necessary and essential element in production management. Inventory is considered the bridge between production and consumption. Every shopkeeper wants to raise inventory levels to quickly respond to customer needs; production and operations staff also like to have a large inventory because it makes it easier to plan production. However, the finance department always wants inventory to be kept at the lowest level because the money in the inventory will not be spent on another item. Therefore, inventory management is an indispensable inventory management principle.

Inventory management is undoubtedly an extremely important job in the business. The shortage or excess inventory has a huge impact on the cost and growth strategy of each business. If your position in the business is the operations or warehouse manager, it’s not hard to realize how difficult it is when it comes to managing inventory. Especially when we must make a report on the units, the number of items, and the location of each item, your responsibility is also to make sure that there is always adequate stock to satisfy customers’ needs in order. Managing all of these numbers and data manually is surely not an easy task. If your reports don’t show the exact volumes of stock, you’ll meet stock outages, which is a nightmare in inventory management. Also, many other extremely huge fines and penalties can be caused by inaccurate reports of inventory.

To solve the difficult problem related to inventory, much professional inventory management software is appearing on the market from domestic and foreign suppliers. Each software is developed to bring the ability to respond well to the needs of users in different fields, for certain requirements. This software when put into use, improving maximum work efficiency, bringing professionalism in warehouse management as required.

Table of Contents

What is inventory management software?

Inventory management software is defined as software developed specifically to serve the purpose of tracking and managing the inventory categories of items through different stages in the supply chain system. Some outstanding features of this software could be listed out like stock level management, item classification, order and purchase tracking, barcode or QR scanning, and automatically reorder points.

In short, inventory management software definition is briefly “a tool that helps automate every part of inventory and warehouse management procedure, offering the users an effective solution to manage and track all the inventory, purchasing, accounting data all at once”. As Mohammed Ali, CEO of Primaseller indicated, “inventory management software notifies you any time when something happens with your inventory stock”.

Different scales of different businesses could require different systems. Retail businesses could scale down the systems to focus on only simple tasks such as maintaining inventory data and inventory levels, whereas businesses with more complex supply chains often need to resort to the inventory management functionality integrated with ERP Systems or more strong inventory management software that provide users with more features.

Moreover, depending on the complication of your requirements of tracking and physical inventory requirements, your business may need to choose software offering features that support multiple sale channels at once, multiple inventory management.

Depending on the complexity of your asset tracking and physical inventory needs, you may require features to support multiple sales channels, multiple warehouse management, and a mobile app. We’ll get into more detail below. Due to the undeniable vitality of the inventory management software in the daily operations of any business, it’s crucially important to select carefully a solution that offers reliable, efficient features meeting your needs.

>> Read more: Expert’s guide on 21 must-know inventory management techniques

Inventory management software benefits

Good inventory management will help goods circulate stably and reduce inventory. And there are many benefits of inventory management software for businesses that will be detailed below.

Normally, if enterprises use manual methods in managing large warehouses, goods management will be extremely difficult because it is easy to make mistakes in the recording process, not be able to actively take the initiative in the import-export process goods, as well as taking a large amount of time with the inventory management.

Replacing manual management with warehouse management software will help businesses save time, costs, and many other benefits. Inventory management software can streamline the procedure of inventory management and tracking. Whether you are a manufacturer, a warehouse manager, or a retailer, a good inventory management software, assisted by comprehensive inventory management systems updating in real-time will give you an overall look at your existing data of inventory, no matter how or where all of your goods are scattered.

Inventory management software best save human resources

Personnel costs will be highly expensive when there are a large number of items to manage because it means there needs a lot of employees to work directly at the warehouse. If businesses use these solutions, the inventory management software costs less than personnel costs for sure. And it will certainly minimize the number of employees; At the same time, it facilitates easy human resource management for managers.

Inventory management software accurately manages inventory quantities

When using inventory management software, in addition to optimizing the storage and making the most of the storage space in the warehouse, this software also helps businesses to manage inventory most accurately, based on information fields about models, specifications, batch numbers, expiry dates,…

Always knowing the number of goods and items will help businesses always provide customers with the products they want quickly and fully. Moreover, through the warehouse management software, the manager will have an overview of the inventory in all warehouses, helping to minimize inventory and avoid stagnant capital.

>> Read more: What is inventory management models? 3 Types of different models

Inventory management software specify and rate each item

Good inventory management software best supports the management of inventory goods in warehouses in many different units (km, m, cm, tons, weights, oats, kg, bags, barrels, bottles, jars, blisters…), thanks to which it is simpler than ever to accurately determine the stock level of the inventory items in stock.

For example, in the supplies warehouse of a drug and medical supplies manufacturing and distribution enterprise: there are 100 Bionic boxes, 15 Bionic boxes, 3 blisters, and 7 Bionic pills. These parameters are easily managed on the inventory management software.

Besides, when linked with accounting software, the inventory management software also supports the calculation of the number of raw materials before being put into production, calculating product costs… calculating the norm of raw materials for a product.

Inventory tracking

Inventory management software benefits include incorporating various other vital systems to enhance inventory management by tracking and analyzing all your inventory items in real-time, giving you the location and the supplying process of your items throughout your sales channels. This automation eradicates human error while dealing with a manual, full-of-spreadsheet system in the managing process.

It’s enormously helpful when knowing exactly where a piece of an item is when it’s time to sell it. The system will offer you a one-stop solution to track the exact place where the product is staying and keep reporting to you about its location and condition out the warehouse to the customer. Inventory management software frees your hard work.

Main features of the inventory management system of software

Inventory management software is made up of several key components that work together to create a cohesive repository of multiple organizational systems. These features include:

Rearranging point

If the inventory reaches a specific threshold, the company’s inventory management system can be programmed to ask the manager to rearrange that product. This helps companies avoid running out of products or having too much capital backlog.

Asset track

When a product is in a warehouse or store, it can be tracked via barcodes and/or other tracking criteria, such as serial number, batch number, or modification number. Today, inventory management software often uses barcode tracking, radio frequency (RFID), and/or wireless technology.

Service management

Companies that are primarily service-oriented rather than product-oriented can use inventory management software to track the cost of materials they use to deliver services, such as making supplies clean. This way, they can attach prices for their services to reflect the total cost of implementing them.

Product identification

Barcodes are usually how order and product data are entered into the software. Barcode readers are used to reading bar codes and look up information about the products they represent. Radiofrequency identification (RFID) tags and wireless product identification methods are also increasingly popular.

Modern inventory software programs can use QR codes or NFC tags to identify inventory items and smartphones as scanners. This method provides an option for businesses to track inventory using barcode scanning without purchasing expensive scanning hardware.

Inventory optimization

Fully automatic demand forecasting and inventory optimization system to achieve important inventory optimization indicators such as:

- Reorder points: number of units that will trigger additional orders.

- Order Quantity: Number of units that need to be reordered, based on reordering points, in stock, and in-stock on order.

- Potential customer demand: the number of units to be sold in the lead time.

- Quantity in stock: number of days remaining before release if no re-orders have been made.

- Accuracy: expected accuracy of the forecasts Wikipedia.

3 Best inventory management software

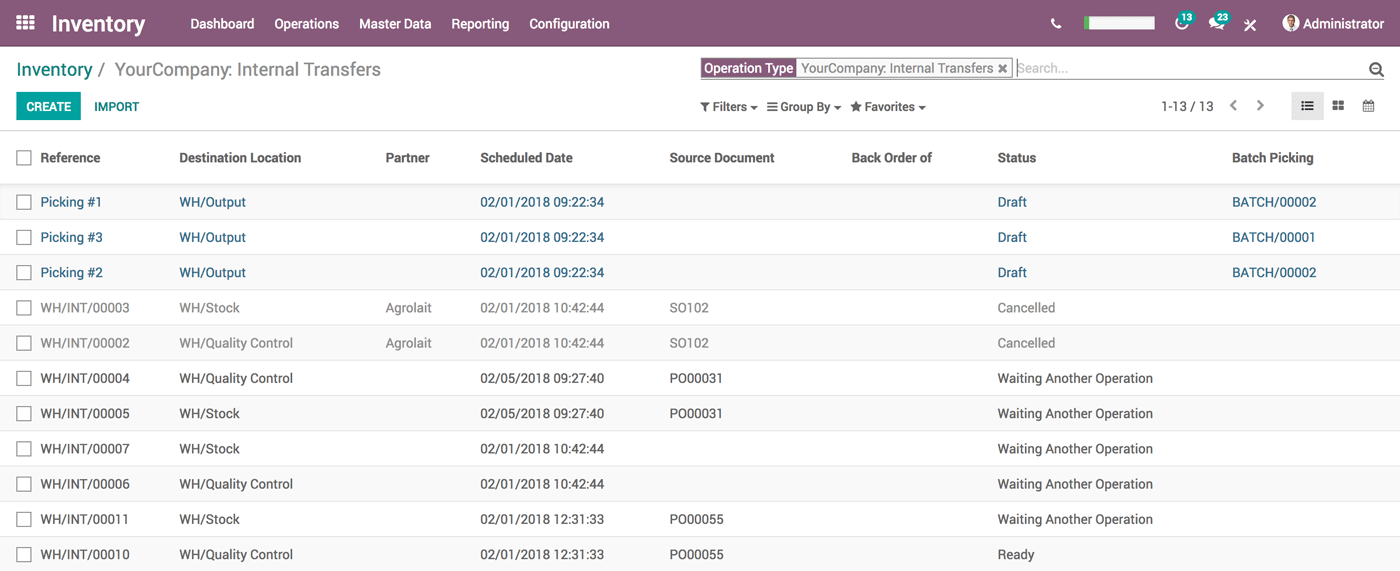

Odoo

Pricing: About the inventory management software price, of the several modules the vendor offers, the first two are available free of cost. You’ll need to pay for any additional module beyond that.

Odoo is an open-source solution providing users with a wide range of features specifically in managing different business functions such as eCommerce management, CRM, POS, supply chain, and inventory management.

Odoo inventory management software ERP permits users to manage and track various delivery orders, dropshipping orders, receptions, and requests for inventory items. The special modules also support various shipping providers such as UPS, DHL, FedEx, or even local post offices. This feature makes the process of managing shipping operations much easier and more convenient.

The software also provides a wireless barcode scanner feature, you can scan your items’ barcode using Wi-Fi, Bluetooth, or direct connections such as USB. The providers also offer an automatic integration with other modules in the ERP software ecosystem of Odoo, so there’s no need for you to manually keep updating all the inventory and accounting records whenever the product is sold.

For customer support requirements, you could also easily contact Odoo via portal requests and phone.

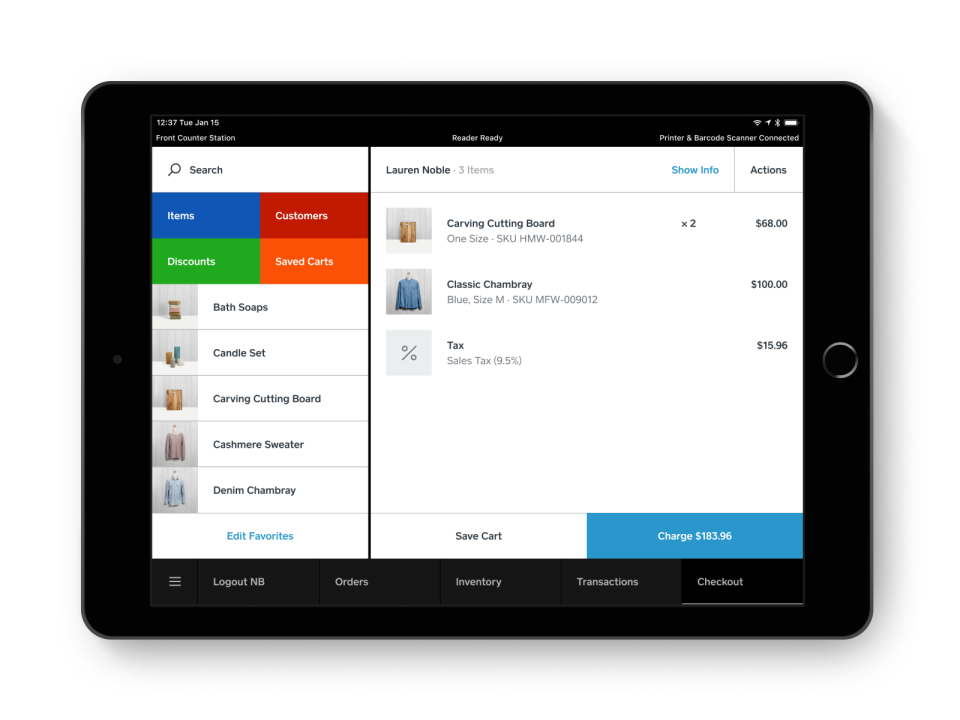

Square for Retail

- Free plan: Offer basic features including management such as payment, cart, customer, or barcode scanning, etc.

- Paid plans: From $60 per month, provides you with more advanced features like inventory transfers, vendor management, or purchase management.

Square for Retail is designed as a retail management software that runs on cloud-based systems. Its main duty is to help businesses to manage their multichannel retail operations. Some vital features that this software provides could be listed out as inventory management, website development, order management, purchasing management, and data collecting and reporting.

The Square’s free plan did allow the users to manage their inventory items and data as well as track and count the stock. The low stock alerts notifying users any time the inventory levels drop lower than the order volume are also available with Square’s free plan. This key feature enables you to refill your inventory items before any unexpected stock outages affect the business’s normal operations.

You could also easily contact Square via portal requests, email, live chat, social media, and phone for customer support requirements. This brings a wider range of contact options than that of Odoo.

Zoho Inventory

- Free plan: Only 25 orders available for each online and offline purchases.

- Paid plans: From $49 per user per month and unlimited online and offline order supports per month.

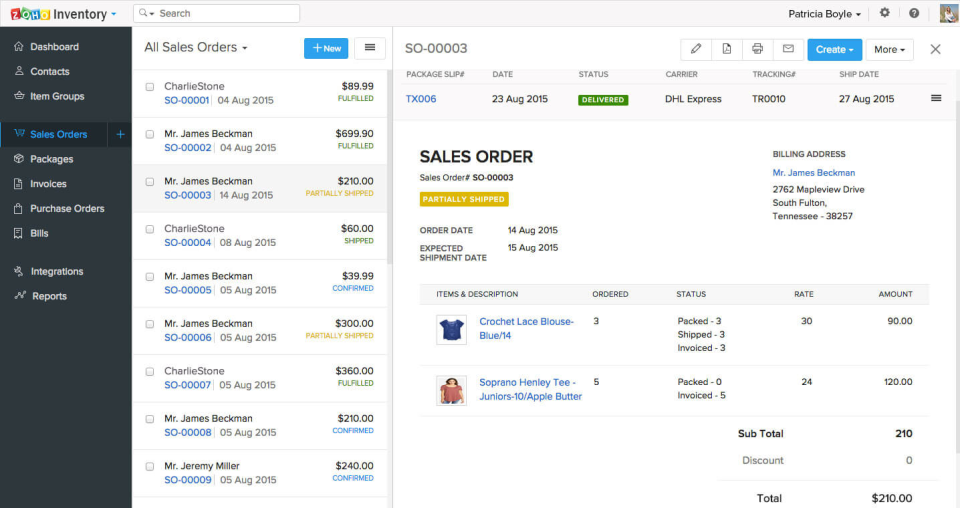

Similar to Square, Zoho Inventory is also a cloud-based inventory management software whose main features include warehouse management, inventory management, and multichannel selling.

Zoho’s free plan allows up to 2 users to manage multi-channel inventory orders of the business at once. They can also track the shipping process and all other activities involving the warehouse. The integration with other eCommerce platforms is also available with the free plan, permitting you to control purchases made on these platforms.

For customer support options, Zoho provides users with quite a wide range of channels such as a self-service knowledge base, FAQs, forums, email, and phone support.

Bottom lines

The use of inventory management software helps businesses be more proactive in using resources and distributing goods efficiently. Moreover, the software warehouse control also helps you to limit the losses in the material warehouse caused by your employees.