Inventory management is an essential part of business operation. You will have to face the inefficient and uncontrollable inventory process, missing inventory, out-stock, excess stock and more if you don’t have an excellent inventory management method. However, managing all activities and processes of the warehouse directly is not easy. That is why you should apply an Inventory management system.

So, what is an Inventory management system? Is it worth the amount of money you spend?

These are the common questions of any business when they consider applying an inventory management system. This blog will give you helpful information about inventory management system types, features and benefits that helps you make the best decision.

Table of Contents

1. What is an inventory management system?

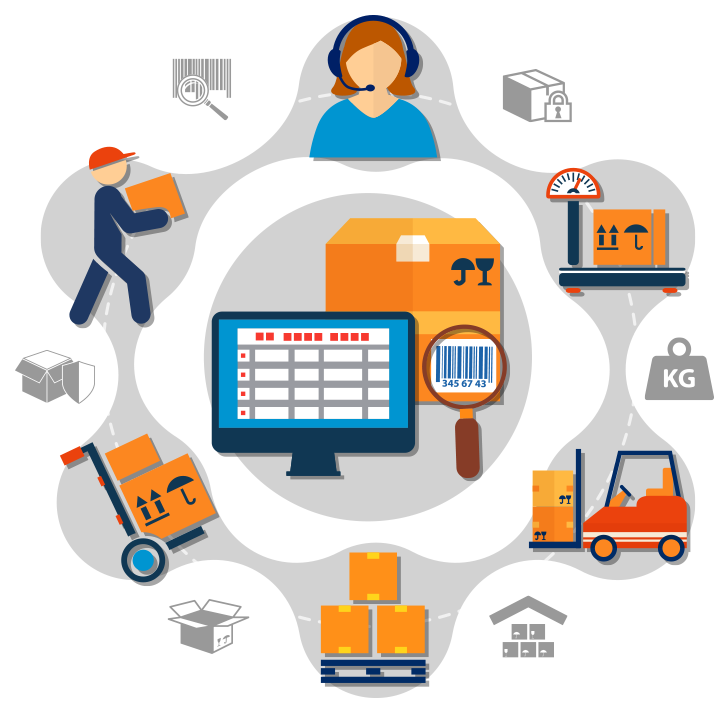

The inventory management system definition is very easy to understand. An inventory management system is the blend of innovation (equipment and programming) and cycles and techniques that manage the checking and support of loaded items, regardless of whether those items are organization resources, crude materials, and supplies, or completed items fit to be shipped off sellers or end purchasers. A total inventory management system comprises of:

- A system for recognizing each stock thing and its related data is standardized identification marks or resource labels.

- Equipment apparatuses for perusing standardized tag marks include handheld scanner tag scanners or cell phones with standardized tag filtering applications.

- Inventory management system gives a focal data set and perspective for all stock, combined with the capacity to examine information, create reports, conjecture future interest, and the sky’s the limit.

- Cycles and arrangements for marking, documentation, and revealing. This ought to incorporate an inventory management system like Just in Time, ABC Analysis, First-In-First-Out (FIFO), Stock Review, or another demonstrated technique.

- Individuals who are prepared to follow these strategies and cycles.

Inventory management changes continually. Consistently, deals, returns, new receipts – even harm and robbery – influence your stock levels. While overwhelming, compelling stock administration and stock control are prominent in a fruitful retail or discount business.

Adequately overseeing stock gets more earnestly as your business scales and the measure of stock you are taking care of increments. Exploiting innovation can make things simpler for yourself and your workers. This is the reason an inventory management system is priceless to any retail business.

2. Inventory management system types

There are four different types of inventory control systems available today: Perpetual inventory systems, Periodic inventory systems, Barcode inventory systems and Radio frequency identification (RFID) systems.

2.1. Perpetual inventory systems

This system updates the database frequently. It makes sure that all inventory changes like receiving, relocating, using, scrapping, selling are scanned into a centralized computer system. Perpetual inventory system systems can track the delivery of inventory accurately and handle minimal physical inventory counts.

This sort of inventory control system works best when combined with a database of inventory amounts and bin locations that is kept up to date in real-time by warehouse employees who utilize barcode scanners.

2.2. Periodic inventory systems

Unlike perpetual inventory systems, this one can’t track inventory periodically. Businesses can know the beginning and ending inventory levels during a specific period instead of the real-time situations.

The operating principle is straightforward, based on the beginning and ending inventory. The previous period’s ending inventory is assumed as the following beginning inventory. Performing an inventory count generates the period’s ending inventory. Furthermore, the count is updated when new things are added to the inventory throughout the period. Businesses may choose LIFO or FIFO, or another inventory management method to calculate the cost of the ending inventory.

2.3. Barcode inventory systems

This system is more accurate and efficient than any manual process. When a worker uses stationary or handheld scanners, the barcode systems will update items scanned automatically. This system is considerably faster than manually counting and recording items. Integrating barcodes into a centralized inventory management system makes it simple to preserve accurate records.

2.4. Radio frequency identification systems (RFID)

This inventory systems use active and passive technology to manage inventory movements. Active RFID tags use fixed readers to detect items when they are moved. There is no need for scanning. While passive tags must be scanned; however, numerous tags may be read at the same time without requiring line of sight, making the procedure significantly faster than scanning individual barcodes.

3. What are the functions of the inventory management system?

3.1. Streamline inventory process – one of the most critical inventory management system features

This is the key function of the eCommerce inventory management system that helps you arrange and track your inventory process efficiently without spending too much money. Instead of going to your warehouse directly, you can control the progress of inventory flow, as well as employees’ activities.

3.2. Control stock

Inventory Management Software allows for multi-level stock management. Managing and maintaining the correct balance in inventory is sometimes a difficult endeavour. Having too little stock can result in a stock-out, which can upset consumers and result in a loss. But having too much inventory can take up warehouse space, and businesses have to hire stock. In any case, the company has to spend more money. Inventory Management System monitors low stock levels and allows you to set up automated reordering for each product. Thus, you can lower the danger of purchasing too much.

3.2. Manage delivery

The slow delivery can lead to a slack inventory process and make customers disappointed. With inventory management software, you can control the timesheet of each stage, find out the problem and avoid the incident risks.

3.3. Forecasting and planning

Through the insights offered by the Inventory System, you may determine the possibility of building numerous regional warehouses near important clients to boost efficiency and improve service levels. Besides, the data in the inventory system will help you to analyze the current situation, identify the problems, forecast the risks the company can get and create a plan for next month.

3.4. Inventory reports

Instead of collecting data and using paper to record them, you don’t have to take too much effort to make a report because of the reports function of the inventory management system. All kinds of inventory reports, such as low-stock reports, perpetual inventory validation reports, and inventory projection, will be sent to you.

3.5. Track serial number of inventory

Serial-number tracking is one of the important features in the inventory management system. From the time the inventory is received until it is released, the program handles an infinite number of serial numbers. The data is saved in the system indefinitely for future purposes.

4. Inventory management system benefits and drawbacks

Inventory management system advantages are the ability to reveal the number of segments or fixings you need to make or collect your result. You may wind up with an abundant inventory management system without this data, disintegrating your primary concern, or with inadequate inventory to fulfill client needs. Here are some advantages and disadvantages of this inventory management system.

4.1. Advantages of the Inventory management system

Simplified inventory management

Perhaps the biggest benefit to using an inventory management system is that it makes the process of dealing with your inventory a lot simpler, saving you time, money and, quite frankly, sanity.

With supply and demand markets changing consistently and your inventory levels constantly fluctuating, inventory management software assists with staying away from the danger of human error via automating your key business processes.

Reduced risk of overselling

Overselling is a major challenge for online sellers, often resulting in loss of control, disappointed customers and in some instances, being suspended from marketplaces such as Amazon and eBay.

By synchronizing your orders and inventory across each of your online marketplaces and eCommerce platforms, the inventory system ensures that stock levels are adjusted each time you make a sale.

Greater cost-savings

By streamlining your inventory management system, you not only stand to eliminate the inventory costs associated with human error, but you can also benefit from further cost savings. It can improve your chances of shortening your supplier lead time through better supplier management relationships.

It also allows you to reduce excess and obsolete stock, not to mention the subsequent costs incurred, by establishing your par levels and calculating your safety stock. It can improve your opportunities of shortening your provider lead time through better supplier management relationships.

4.2. Disadvantages of the Inventory management system

System crash

One of the biggest problems with any automated system is the potential for a system crash. A degenerate hard drive, blackouts and other specialized issues can bring about the deficiency of required information. In any event, companies are interrupted when they can not get the information they need. Entrepreneurs ought to back up information routinely to secure against information loss.

Reduced physical audits

When everything is automatized, it is not difficult to forego tedious physical inventory audits. They may no longer appear to be fundamental when the PCs are tackling their job. In any case, it is essential to keep on doing regular audits to distinguish misfortunes like deterioration or breakage. Audits also help entrepreneurs determine expected internal theft and control the computerized inventory system.

Malicious hacks

An inventory system connected to point-of-sale devices and accounting is a valuable resource to hack into searching for potential financial information or personal details of owners, vendors or clients.

However, while you will require an inventory management system, which one you pick is altogether up to you. There are innumerable various frameworks you can receive, going from basic ways to deal with extensive arrangements.

5. How does an inventory management system work?

That being said, an inventory management system is just pretty much as outstanding as how you use it.

It is worth the additional time and cash to choose the suitable inventory management system types set up by the specialists who made the product. Work with them to ensure you use the appropriate methods and highlights to get the most value for your money.

We should investigate some stock control methods you may decide to use in your stockroom.

5.1. Economic order quantity

Money request amount, or EOQ, is a recipe for the ideal amount an organization needs to buy for its stock with many factors like all-out expenses of creation, request rate, and different variables.

The general objective of EOQ is to limit related expenses. The recipe is utilized to distinguish the best number of item units to restrict purchasing. The equation also takes the number of companies to convey and put away stock unit costs. This helps free with expanding tied money in stock for most organizations.

5.2. Minimum order quantity

The minor request amount (MOQ) is the littlest measure of set stock a provider will sell on the provider side. If retailers can not buy the MOQ of an item, the provider will not offer it to you.

For instance, stock things that cost more to create commonly have a more modest MOQ than less expensive things that are simpler and more practical to make.

5.3. ABC analysis

This inventory management system features three classes to recognize things that vigorously affect generally speaking stock expenses.

Category A fills in as your most essential item that contributes the most to by and enormous benefit.

Category B is the items that fall someplace in the middle of the most and least significant.

Category C is for the little exchanges fundamental for generally speaking benefit yet do not make any difference much separately to the organization out and out.

5.4. Just-in-time inventory management

Just In Time (JIT) is a procedure that orchestrates crude material orders from providers directly associated with creating plans.

JIT is a fantastic method to reduce diminish stock expenses. Organizations get stock dependent upon the circumstance instead of mentioning unnecessarily and gambling dead stock. Deadstock is stock that was never sold or used by customers being taken out from deal status.

5.5. Safety stock inventory

A well-being inventory management system is the additional stock being requested past anticipated interest. This method is utilized to forestall stock-outs regularly brought about by inaccurate expecting or unexpected client interest changes.

5.6. FIFO and LIFO

LIFO and FIFO are strategies to decide the expense of stock. FIFO, or First in, First out, accepts the more established store is sold first. FIFO is a terrific method to keep stock new.

LIFO, or Last-in, First-out, expects the more up-to-date stock is commonly sold first. LIFO keeps stock from turning sour.

5.7. Reorder point formula

The reorder point recipe is a stock administration procedure that depends on a business’ buy and deal cycles that fluctuate on every item premise. A reorder point is typically higher than a well-being stock number to factor in lead time.

5.8. Batch tracking

Bunch following is a quality control inventory management system method wherein clients can be gathering and screen a bunch of stock with comparative characteristics. This technique assists with following the lapse of stock or following bad things back to their unique clump.

5.9. Consignment inventory

In case you are considering your nearby transfer store here, you are spot on. Transfer stock is an agreement when a consigner (seller or distributor) consents to give a representative (retailer like your #1 transfer store) their merchandise without the proctor paying for the stock forthright. The consigner offering the stock claims the merchandise, and the agent pays for them just when they sell.

5.10. Perpetual inventory management

A never-ending inventory management system is just considering stock as soon as it shows up. It is the most fundamental inventory management system method and can be recorded physically on pen and paper or on a bookkeeping page.

Final Thought

Some businesses, especially small ones, take the inventory management system lightly and think that they can handle and control inventory effectively. Until facing inventory problems such as missing items, over storing, delivery delays, they just consider investing in inventory systems. The spending for it is not cheap, but it will guarantee the sustainability of your business and help you to avoid risks that cost a lot of money.

So, the advice for you is to research and find an inventory management system that is suitable for your company. If your one is small and medium, you should choose a system having a reasonable cost and simple features, like Odoo. With Odoo Inventory module, you and any non-tech individuals can add any feature you want easily without knowing much about coding. If you have any wonder about Odoo, just contact us! We will help you to have the best inventory management system solution.