Inventory management plays a vital role in business operations. It ensures adequate inventory to meet your company’s needs, unwasted inventory, and reduced costs of warehouse activities. Enterprises want to manage their inventory effectively; however, there are some challenges in inventory management you can face with.

Understanding your client’s necessities and settling on savvy choices on the most proficient method to oversee them through stock is a test in the current purchasing environment. There are numerous issues looked at in inventory management, yet these issues accompany challenges in inventory management. Dealing with your inventory is more perplexing than it might appear. Here are the most common inventory management problems and solutions to defeat them.

Table of Contents

- What Are The Challenges in Inventory Management?

- Top 11 Common Challenges in Inventory Management

- Inconsistent Tracking

- Not Using Good Vendors – The Most Common Challenge in Inventory Management

- Not Having Performance Measurement Parameters in Place

- Transparency

- Poor Process – The Risky Challenges in Inventory Management

- Inadequate Software

- Managing Warehouse Space

- Manual Documentation

- Problem Management

- Labour Collaboration

- Production Planning

- Best 9 Solutions to Overcome Challenges in Inventory Management

- Eliminating Mis-picks in Your Warehouse

- Reducing Oversells in Your Store

- Maintaining An Excellent Warehouse Team – Effective Solution for Challenges in Inventory Management

- Turn “Out of Stock” into “in Stock”

- Avoiding Lost Inventory

- Monitor Suppliers Service

- Inventory Forecasting and Create A Plan

- Enhance Productivity with Inventory Software – The Best Solution for Challenges in Inventory Management

- Leverage Lead Times

What Are The Challenges in Inventory Management?

We as a whole realize that commercial centers are continually evolving. First off, the global exchange scene is more unsure than at any other time. What is more, eCommerce is driving expanded rivalry from merchants worldwide, both enormous and small. Furthermore, with clients being requesting and more vocal about their encounters, the need to offer excellent assistance at maximum velocity is turning into the standard.

Successful inventory management influences each feature of your business and has a considerable effect on your primary concern. You can precisely occupy requests, from your warehousing expenses to work expenses, on schedule messes up cost time and cash.

Inventory management works out in a good way past keeping up stock checks. Present-day inventory management deals with each period of the item life cycle. It incorporates modules for deal gauging, inventory network the board, item requesting, stockroom the executives, and client satisfaction.

Inventory management can help you deal with your stock levels, alert you when it is an ideal opportunity to reorder and distinguish the most expense-effective strategies for requesting and putting away items. It can create paperless picklists, enhance stockroom traffic, and give protection to stay away from mis-ships. Such things could be recognized as challenges in inventory management.

Running a productive retail activity, keeping up the legitimate stock, and streamlining distribution center tasks are only a few things that demonstrate inventory management’s significance. There is no lack of difficulties in dealing with inventory management challenges.

Top 11 Common Challenges in Inventory Management

Here are some problems faced in inventory management, which can affect the inventory management objectives in some scales and to some extent:

Inconsistent Tracking

Utilizing manual management following techniques across various programming and accounting pages is tedious, repetitive, and helpless against mistakes. Indeed, even independent ventures can profit from a robust stock global positioning framework that incorporates bookkeeping highlights.

While we are focusing on matters specific mainly to inventory management, the key takeaway here is “visibility”. Investing in upgrading your processes, software, and equipment as part of a warehouse modernization effort to improve data capture and analytics helps solve challenges in inventory and up and down your supply chain.

Not Using Good Vendors – The Most Common Challenge in Inventory Management

This may appear to be an easy decision; however, it is likewise a typical issue. Tracking down a decent merchant is a refined harmony between somebody reliable and somebody who does not again charge a bomb.

Fortunately, there are a few survey sites today where you can discover veritable merchant audits before picking to proceed with them. If a specific merchant does not meet your quality or administration norms or defers shipments and influences your stock administration, drop them like a hot potato! If you sell a specialty item, consider total vertical mix, so you have command over assembling, requesting, and therefore your stock levels.

Not Having Performance Measurement Parameters in Place

Measure physical assets just as intangibles to forestall stock issues. Consumer loyalty evaluations, stock turnover, or even only your functioning capital are incredibly significant. Item chiefs should screen day by day fill-rates and stock turnover dependent on your business cycles.

Transparency

The best organizations will incorporate straightforwardness into their satisfaction to ensure representatives and clients realize what is befalling things. Indeed, even with the unique challenges in inventory management in internet purchasing, request problems can happen in any case. If your client knows about delays, they can change their assumptions and feel confident that their thing will, in any case, show up. Correspondence and straightforwardness are crucial for your prosperity. This incorporates telling the client the second something they are hanging tight for returns stock.

Poor Process – The Risky Challenges in Inventory Management

Inventory management controls at the distribution center are activities escalated and include a few stages, including getting and putaway, picking, pressing, and transportation. The test is to play out every one of these errands in the most effective manner conceivable.

Inadequate Software

To scale inventory management programming to help complex coordinations, it needs to incorporate your current business measure stages. The challenges in inventory management and solutions undertaking are browsing many inventory management arrangements and dominating a large group of highlights requiring preparation and progress support.

Rather than tallying the whole stock at one time, businesses count various things in the stockroom. Cycling calculating is a factual examining procedure. The computing of specific items is utilized as a kind of perspective for the remainder of the stockroom. If your stock is off in the cycle tallies, you will probably track down similar errors in different zones. In like manner, if the cycle checks show your store is exact, you are bound to have precise tallies all through the distribution center.

Managing Warehouse Space

Productively overseeing space is a scary undertaking. Arranging and planning stockroom spaces with inventory management stages helps you better control the circumstance of new stock conveyances. It can represent significant components, like accessible space. Peruse more about the contrasts between stockroom executives and challenges in inventory management.

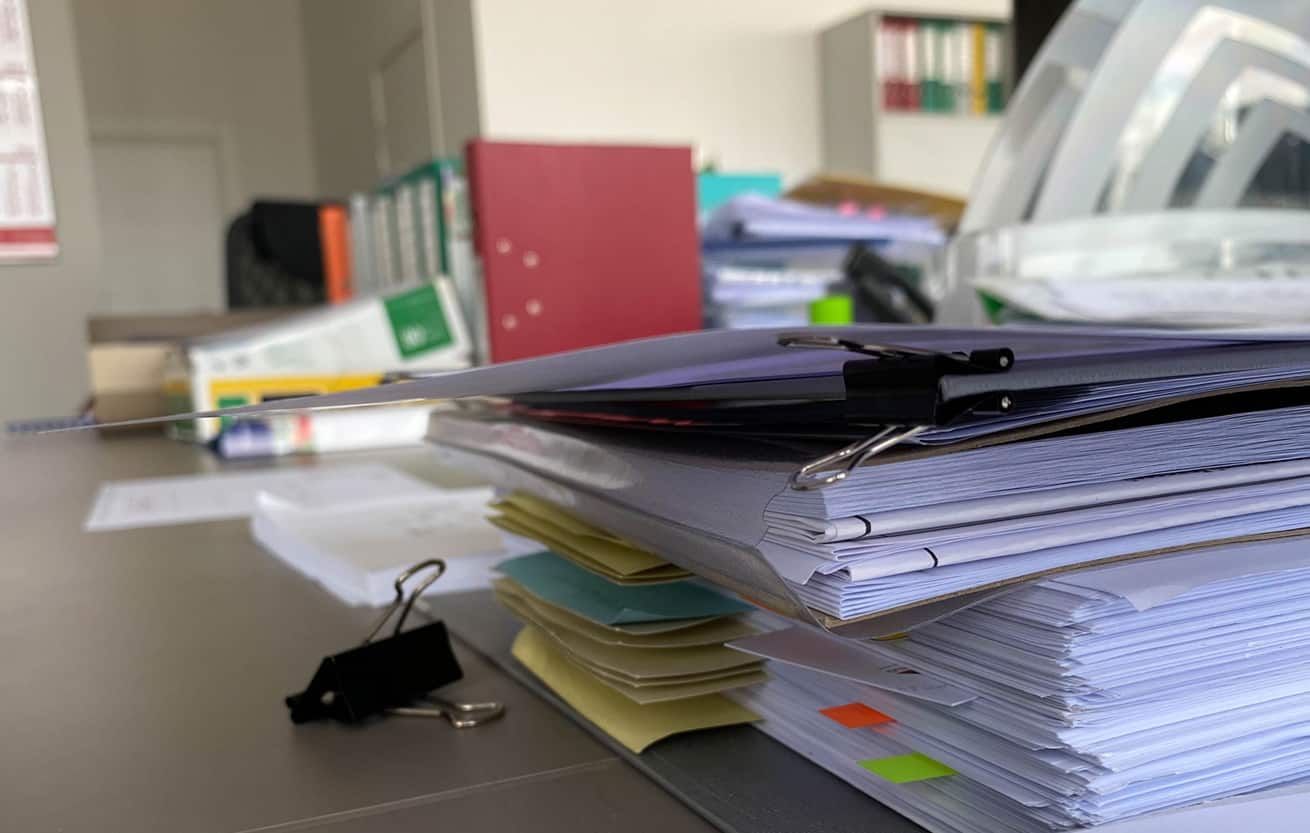

Manual Documentation

Overseeing management with desk work and manual cycles is monotonous and not secure. Furthermore, it does not handily scope across various stockrooms with heaps of control.

Problem Management

The transient and delicate stock needs specific designs for care and capacity. What is more, it is that the high-esteem stock necessities explicit misfortune avoidance methodologies and inventory management.

Labour Collaboration

Cooperation among labors is one of the prevalent problems faced in inventory management. Communication and collaboration are keys to ensuring that their warehouse process is implemented successfully. It’s far more challenging to spot inventory patterns and find methods to improve when departments are indifferent about exchanging information. If the information flow is slow and disrupted, employees cannot know about tasks, requirements, progress, and the situation of work. As a result, businesses will get into trouble with warehouse issues.

Production Planning

Production planning is essential for minimizing production delays and costs. In each month, businesses have to summarize their production results, find out the problem and solution, and set targets for the next month. Their production plans are created in detail, based on the solution and monthly KPI. If not done correctly, it might influence sales estimates and project timing.

Best 9 Solutions to Overcome Challenges in Inventory Management

You know the significance of inventory management and the effect it has on your activity. In any case, there are difficulties and issues that you need to fight continually. Imagine a scenario where we could show you there are arrangements.

Eliminating Mis-picks in Your Warehouse

Missteps altogether picking are more outrageous than you may than from the outset. There is the expense of the thing and transportation costs if it some way or another gets conveyed. If it is returned, you have the deal with the price and conceivable harm to the thing. If it is gotten before delivery, it takes time to return it to the stock, get the right thing, and record everything. There are likewise covered-up costs, including despondent clients and the potential for harm to your standing.

Challenges in inventory management can assist with lessening the recurrence of mis-picks. Its blunder counteraction highlights remind laborers to twofold check their picks. Likewise, its shrewd picking innovation produces a proficient pick list, so laborers invest less energy in picking by and large.

Mis-picks are not generally the deficiency of obsolete programming. It assists with having roused laborers who genuinely care about picking the right items during the first run-through.

Reducing Oversells in Your Store

Oversells is an income executioner. An oversell is when you have sold a more significant number of items than what is at present in stock. This happens typically when there are challenges in inventory management, and you show that the distribution center has a more significant number of items than it does.

It is a one-two punch when you are in an oversell circumstance. You have clients that need to purchase your items, and you can not satisfy them. In an ideal situation, baffled clients may discover different things to buy. In the most pessimistic scenario, customers might be enticed to go straightforwardly to your rival and purchase the item you do not have available to sell. If they have a positive encounter, you may lose future deals.

When you are overselling, you hazard losing a deal or deferring item conveyance, which can harm your relationship with your client.

In the present multi-stage, multi-channel deals climate, you should have a solid framework for following the management and ceaselessly updating tallies across each deal channel. Stay away from inventory management programming that does not continually refresh when deals happen.

An unbending interaction, supported by a robust inventory management framework, can help lessen oversells by precisely following stock levels. Cycle tallies ought to be led consistently with higher recurrence for the things that make up the central part of your income.

Maintaining An Excellent Warehouse Team – Effective Solution for Challenges in Inventory Management

If your distribution center is consistently a wreck despite having a top-of-the-line IMS, it is an ideal opportunity to reconsider your stockroom group.

A few groups adjust well to distribution center life. They love the everyday upkeep and have the ability to run it effectively because of the broad scope of responsibility highlighted.

Effective frameworks can likewise keep laborers propelled. By creating a paperless picklist and recording stock development by examining it, groups can work more productively. Improved pick courses can save time and mileage in colleagues by lessening travel time in the distribution center. Exact stock checks can ease dissatisfaction when pickers can not find the required things.

Lessening the pressure and permitting colleagues to work productively can help hold top entertainers. That is key in the present work market. Even with COVID-19 prompting soaring joblessness numbers, discovering, preparing, and maintaining distribution center laborers stays a test. If you have the correct colleagues on board as of now, and you can keep them glad – and flawless – you will be on top of things.

Turn “Out of Stock” into “in Stock”

Your inventory management system should allow you to set restock levels, maintain enough safety stock, and automate orders when the stock levels reach preset counts.

Avoiding Lost Inventory

There is nothing more awful than acknowledging you have stock to satisfy orders. However, you can not find it. It is infuriating for everybody included. You have gone through the cash to purchase the things. However, you can not sell them or even discover them!

Consider it along these lines: Let’s say you lose a bed with 100 things that cost you $50 each to purchase and transport to your stockroom. Immediately, you are out $5,000. Add to that the standard gross edge you make on selling these things. In this model, we should expect your gross edge is 20%. That adds another $1,000 in the income you have lost. Likewise, you will presumably wind up supplanting that equivalent stock, so add another $5,000. We are presently up to $11,000 in stock expenses and lost income before you can even consider recuperating any of the fees.

Monitor Suppliers Service

There are some risks if your vendors don’t accomplish the services they promise. Your suppliers can deliver materials late or missing products. That is why supplier data, such as shipment mistakes, damaged or faulty items, and missed delivery appointments, should be monitored and tracked. Measure the performance of your suppliers to identify and resolve supply chain problems, decrease complexity, and streamline logistics.

Inventory Forecasting and Create A Plan

Based on internal and external data, you can analyze the change in demand and forecast the needs for inventory. After that, it’s easy for you to set monthly goals and make an optimal plan to achieve KPI. To prioritize your top goods, use an inventory management system with comprehensive demand forecasting and reporting tools. It would help if you considered the availability of the top 20% of inventory, which produces 80% of your consumer demand.

Enhance Productivity with Inventory Software – The Best Solution for Challenges in Inventory Management

It will be time-wasting if enterprises manage their inventory without technology. Additionally, there are some risks with incorrect data when not using the paperless method. To enhance efficiency, you should choose and use appropriate inventory software. You can control inventory and increase warehouse productivity from anywhere globally with mobile solutions and cloud-based applications.

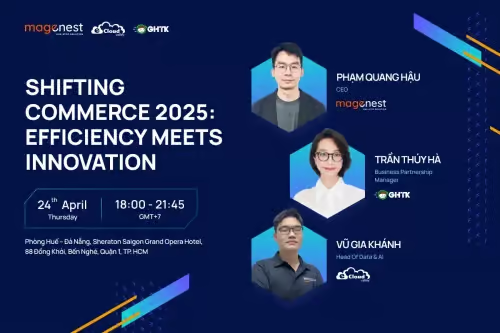

To help you handle inventory issues, there are tons of warehouse management software that have notable functions. One of them is Odoo. Odoo ERP system has a surpassing inventory management module that assists plenty of companies in inventory management. Known as holistic software, Odoo can help you solve all sectors’ problems in your enterprise without needing to integrate with other software.

Leverage Lead Times

When placing orders for high-demand items, keep lead times in mind. Using cycle counting data to create automated reorder points and average lead time, you can track and monitor your stock and avoid overstock.

Final Thought

Conquering the main inventory management problems and solutions in inventory management is a continually continuous cycle. Each distribution center activity ought to be continuously kept watch for approaches to improve profitability and effectiveness. If you are getting things done by hand, utilizing bookkeeping pages, or having an obsolete stock administration framework, it will be hard to accomplish critical additions.

With skilled developers and business specialists, Magenest, the silver partner of Odoo, has helped enterprises solve problems with Odoo solutions. We have a thorough understanding of business challenges and how to address them after working with various partners. Magenest makes sure that you will have the best solution for inventory management with Odoo software.

If you have any requirements, don’t hesitate to get in touch with us!