At its core, an omnichannel warehouse bridges the gap between online and offline operations by providing real-time visibility into inventory across multiple channels. This ensures that customers can access accurate stock information whether they are shopping online or in-store. Additionally, omnichannel warehouses support a variety of fulfillment strategies, from same-day delivery to click-and-collect, allowing businesses to offer faster and more flexible delivery options.

This blog post will explore the transformative impact of omnichannel warehousing on supply chain operations and customer satisfaction, while diving deep into the strategies, technologies, and best practices that businesses can adopt to stay ahead in today’s omnichannel-driven marketplace.

Table of Contents

Understanding Omnichannel Warehouse

Omnichannel Warehousing And Its Role In Modern Supply Chains

Definition of Omnichannel Warehousing

Omnichannel warehousing refers to the integration and coordination of a company’s inventory, order management, and fulfillment processes across all sales channels, both online and offline. Unlike traditional warehousing models, where products are stored and distributed based on singular or limited channels (such as a single eCommerce platform or brick-and-mortar stores), an omnichannel warehouse facilitates the flow of goods across all retail and distribution points. This system ensures that products are available to customers regardless of where they choose to shop, whether it be online, in-store, or through mobile apps.

The omnichannel warehouse plays a pivotal role in modern supply chains by ensuring real-time inventory visibility, flexible fulfillment options, and optimized delivery speed. This type of warehousing is designed to handle the complexities of multiple channels, providing a cohesive system where orders from eCommerce platforms, retail stores, and third-party marketplaces are processed efficiently within the same facility. It centralizes all aspects of warehousing, from storage and picking to packing and shipping, allowing businesses to manage all customer orders from a unified system. This centralization not only improves operational efficiency but also enhances the customer experience by ensuring that inventory is accurately reflected across all sales channels.

Differences Between Traditional and Omnichannel Warehousing

The differences between traditional warehousing and omnichannel warehousing are stark and reflect the broader shift in the retail and eCommerce industries. A traditional warehouse typically supports single-channel distribution, meaning it is often siloed in its approach. For example, a traditional warehouse may be dedicated solely to storing goods for physical retail stores or fulfilling orders from an eCommerce platform. In this model, there is minimal interaction between the systems managing in-store inventory and those handling online sales. This often results in inefficiencies, such as stockouts or overstocks, where products may be unavailable in one channel despite being overstocked in another.

In contrast, the omnichannel warehouse breaks down these silos by centralizing inventory management and distribution for all sales channels. With real-time visibility, an omnichannel system allows businesses to use a single pool of inventory for multiple channels, ensuring better stock utilization. For example, if an item is low in stock for an online order, it can be sourced from a nearby retail store or fulfillment center to avoid a delay. This flexibility is essential for meeting customer expectations, particularly in terms of delivery speed and convenience.

Additionally, traditional warehouses tend to operate in a more static and reactive manner, relying on bulk shipments and scheduled deliveries. However, an omnichannel warehouse is far more dynamic, capable of processing individual orders, managing same-day deliveries, and offering flexible fulfillment options such as in-store pickup (click-and-collect) or curbside delivery. This adaptability allows businesses to cater to customer preferences more effectively while streamlining operations to reduce costs and improve efficiency.

The omnichannel warehouse represents a transformative shift from the rigid, single-channel focus of traditional warehousing to a more fluid, integrated system that supports the complexities of modern retail. By embracing this model, businesses can improve their supply chain efficiency, enhance the customer experience, and better manage the challenges of today’s multi-channel retail environment.

Importance in the Retail Landscape

The Rise of eCommerce and the Need for Seamless Integration

In recent years, eCommerce has become a dominant force in the global retail industry, changing the way businesses operate and how customers interact with brands. The shift towards digital retail has necessitated the evolution of traditional supply chains and warehousing models. The omnichannel warehouse emerges as a direct response to these changes, enabling businesses to manage and integrate multiple sales channels, including online marketplaces, physical stores, and direct-to-consumer platforms, within a unified operational framework.

As customers engage with brands through various channels, businesses can no longer afford to operate in silos. An omnichannel warehouse ensures that inventory is centrally managed and that orders from any sales channel can be fulfilled efficiently. Whether a customer places an order online, via mobile, or at a physical store, the omnichannel warehouse integrates all these touchpoints to streamline operations. This seamless integration allows for real-time synchronization of stock levels, which is essential for providing accurate product availability information across all channels. Without the implementation of an omnichannel warehouse, businesses may struggle to meet the growing demands of a digitally-driven marketplace, leading to delays, stock discrepancies, and dissatisfied customers.

Moreover, the omnichannel warehouse supports businesses in scaling their operations to meet the increased volume of online orders, particularly during peak seasons. As eCommerce continues to grow, having a warehousing system that can dynamically adjust to handle surges in demand becomes essential. The omnichannel warehouse offers the flexibility and scalability that modern retailers need to remain competitive in this fast-paced environment.

Customer Expectations

Today’s consumers expect more from the brands they interact with, and this extends to how products are delivered and managed. One of the most significant changes in consumer behavior is the demand for faster deliveries. With the rise of same-day or even one-hour delivery services offered by major retailers, the omnichannel warehouse must be equipped to handle such expectations. By integrating various fulfillment models—such as ship-from-store, click-and-collect, or direct delivery—the omnichannel warehouse enables businesses to offer a range of delivery options that meet the specific needs of their customers.

Real-time stock availability is another critical factor driving the importance of omnichannel warehouses. Customers expect the information they see online or in-store to reflect the actual availability of products. An omnichannel warehouse provides real-time updates on stock levels across multiple channels, preventing situations where customers place orders for items that are out of stock. This transparency helps build trust with customers and ensures a more reliable shopping experience.

Furthermore, consumers today seek flexibility in how and when they receive their orders. With options like curbside pickup, in-store pickup, or home delivery, customers now have more control over their purchasing experience. The omnichannel warehouse plays a vital role in offering these choices by ensuring that all fulfillment methods are seamlessly coordinated. Whether it’s preparing an order for in-store pickup or shipping it directly from a warehouse, the omnichannel warehouse manages these processes to ensure fast, accurate, and convenient service for the customer.

Key Components of Omnichannel Warehousing

Inventory Visibility

Real-time Inventory Tracking and Management Across All Sales Channels

One of the main challenges in managing an omnichannel warehouse is ensuring that inventory levels are accurately tracked and updated in real time across all sales platforms. In a traditional warehouse, stock might only be updated at certain intervals, creating discrepancies between what is available and what is displayed to customers. However, in an omnichannel warehouse, real-time inventory tracking is essential to avoid issues such as selling out-of-stock items online or holding excess inventory in one location while other channels face shortages.

Real-time inventory visibility allows businesses to synchronize their stock levels across all sales channels, from eCommerce platforms to physical retail locations. This means that when a customer makes a purchase online, the system immediately updates the available stock, reducing the risk of overselling. Similarly, if inventory is low at one location, the omnichannel warehouse system can automatically source products from another warehouse or store, ensuring that customer orders can be fulfilled without delay. This not only enhances operational efficiency but also improves the customer experience, as shoppers are less likely to encounter unavailable items or shipping delays.

In addition to improving fulfillment speed, real-time inventory tracking helps businesses optimize their stock levels across various locations. By having a clear, centralized view of inventory, companies can make informed decisions about where to allocate products based on demand, minimizing the costs associated with excess stock or emergency restocking. This ability to dynamically manage inventory in response to real-time data is a key advantage of the omnichannel warehouse model.

Technologies Supporting Inventory Visibility in Omnichannel Warehousing

To achieve real-time inventory visibility in an omnichannel warehouse, businesses rely on several advanced technologies that help track, manage, and update stock levels with precision. Among these technologies, Radio Frequency Identification (RFID), the Internet of Things (IoT), and advanced Warehouse Management Systems (WMS) play a pivotal role in ensuring that inventory is monitored accurately across all channels.

RFID (Radio Frequency Identification)

RFID technology is a game-changer for inventory management in the omnichannel warehouse. It uses electromagnetic fields to automatically identify and track tags attached to products, allowing for seamless stock monitoring without manual intervention. RFID tags can be scanned from a distance, which makes it significantly easier for warehouse workers to track large volumes of items in real time. This technology eliminates human error in inventory counting and ensures that stock levels are updated instantaneously across all platforms. As a result, the omnichannel warehouse benefits from faster and more accurate inventory tracking, reducing the risk of discrepancies between physical stock and what is displayed online or in stores.

RFID also enhances the ability of the omnichannel warehouse to handle multiple fulfillment methods. For example, when a product is purchased through click-and-collect, the RFID system can quickly locate the item in-store, ensuring that the order is ready for pickup without delay. This level of automation streamlines the entire fulfillment process, making the omnichannel warehouse more efficient and responsive to customer needs.

Internet of Things (IoT)

The Internet of Things (IoT) further enhances inventory visibility by connecting physical devices—such as sensors, RFID readers, and inventory management systems—into a unified network. In an omnichannel warehouse, IoT devices can monitor various aspects of inventory in real time, from stock levels to the movement of goods within the warehouse. For example, IoT-enabled sensors can track when products are moved from one location to another or when they are picked for fulfillment, ensuring that the system is always up to date.

IoT plays a crucial role in ensuring that all locations within the omnichannel warehouse network are synchronized. Whether inventory is stored in a central distribution center or a local store, IoT technology ensures that any changes in stock levels are communicated to the central system, allowing for accurate real-time visibility. This level of transparency is especially important in a complex omnichannel environment, where inventory can be distributed across multiple fulfillment centers, stores, and even third-party logistics providers.

Warehouse Management Systems (WMS)

Advanced Warehouse Management Systems (WMS) are the backbone of any omnichannel warehouse. These systems provide comprehensive oversight of inventory levels, order management, and fulfillment processes, enabling businesses to track stock in real time across all channels. A WMS integrates with other systems, such as eCommerce platforms, point-of-sale (POS) systems, and transportation management systems (TMS), creating a cohesive network that ensures inventory is updated and orders are fulfilled efficiently.

A WMS in an omnichannel warehouse can automatically allocate inventory based on demand, ensuring that products are sourced from the most optimal location for fulfillment. For example, if a customer orders a product online, the WMS can determine whether to ship from a warehouse, a store, or a fulfillment center based on proximity, stock levels, and delivery speed. This level of automation reduces manual intervention, streamlines operations, and enhances the customer experience by ensuring faster and more accurate deliveries.

Moreover, WMS systems can generate real-time reports and analytics, providing businesses with valuable insights into inventory performance. This data-driven approach allows companies to make informed decisions about stock allocation, replenishment, and demand forecasting, further optimizing the omnichannel warehouse for efficiency and profitability.

Seamless Order Fulfillment

Efficient Processing of Orders from Different Sales Platforms

One of the key challenges of managing an omnichannel warehouse is the ability to handle orders from various sales platforms in a cohesive manner. Traditional warehousing models often struggle with siloed operations, where orders from different channels (such as online and in-store) are processed separately, leading to inefficiencies and delays. However, in an omnichannel warehouse, all orders are funneled into a centralized system that coordinates the fulfillment process across all channels.

The omnichannel warehouse operates with a unified view of inventory and order data, enabling it to streamline the fulfillment process. For example, when an online order is placed, the warehouse management system (WMS) in the omnichannel warehouse can automatically identify the best location to fulfill the order, whether it is from a central distribution center, a local store, or another fulfillment hub. This flexibility ensures that the order is processed and shipped as quickly as possible, reducing delivery times and minimizing the risk of delays or stock shortages.

By integrating sales channels, the omnichannel warehouse also supports cross-channel fulfillment, where products purchased through one channel can be fulfilled by another. This level of integration is essential for meeting customer expectations for convenience, especially when they choose to buy online and pick up in-store or return items purchased online at a physical location. The ability of the omnichannel warehouse to facilitate these processes ensures a seamless experience for the customer, regardless of how they interact with the brand.

Various Omnichannel Fulfillment Models

A major strength of the omnichannel warehouse is its ability to support various fulfillment models, allowing businesses to offer flexible options to their customers. These fulfillment models, which include ship-from-store, click-and-collect, and same-day delivery, are designed to meet different customer needs, from fast delivery to convenience. By incorporating multiple fulfillment strategies into the omnichannel warehouse, businesses can improve the customer experience and stay competitive in an increasingly demanding market.

Ship-from-Store Fulfillment

Ship-from-store is one of the most effective omnichannel fulfillment models, allowing businesses to leverage their physical retail locations as fulfillment centers. In this model, an order placed online or through a mobile app is fulfilled using inventory from a nearby store rather than a central warehouse or distribution center. This strategy offers several advantages. First, it reduces delivery times by shipping from a location that is geographically closer to the customer. Second, it helps optimize inventory usage by utilizing stock from stores that may have excess inventory. Finally, it helps reduce shipping costs, as products are shipped from local stores rather than from a single central location.

For example, a customer in a major metropolitan area might place an order online for an item that is available in a nearby store. Instead of the order being fulfilled by a warehouse hundreds of miles away, the omnichannel warehouse system identifies the store with available stock and routes the order to be picked, packed, and shipped from that location. This not only speeds up the delivery process but also frees up capacity in the central warehouse for handling other orders.

Click-and-Collect (Buy Online, Pick Up In-Store)

Click-and-collect, also known as buy online, pick up in-store (BOPIS), is another popular omnichannel fulfillment model that is widely used in today’s retail environment. This model allows customers to place orders online and then pick them up at a physical store, providing a convenient option for those who prefer not to wait for shipping or who want to avoid delivery fees.

In an omnichannel warehouse, the click-and-collect process is seamlessly integrated with the overall inventory and fulfillment system. When an online order is placed for in-store pickup, the omnichannel warehouse identifies the nearest store with the required inventory and ensures that the item is reserved for the customer. The store is then notified to prepare the order for pickup, streamlining the process and reducing the time it takes for the customer to collect their purchase.

Click-and-collect is a highly effective model for improving customer convenience, as it allows shoppers to browse and purchase items online while still enjoying the immediate gratification of in-store pickup. This model also helps reduce the strain on the central omnichannel warehouse by distributing fulfillment tasks to individual stores, making it an ideal strategy for businesses with multiple retail locations.

Same-Day Delivery

Same-day delivery is one of the most sought-after fulfillment options in the modern retail landscape. As customers become increasingly accustomed to fast shipping speeds, businesses are under pressure to provide same-day or next-day delivery services. The omnichannel warehouse plays a crucial role in facilitating these expedited deliveries by optimizing the fulfillment process and ensuring that orders are picked, packed, and shipped as quickly as possible.

In an omnichannel warehouse, same-day delivery is made possible through a combination of advanced inventory management, real-time data tracking, and strategic fulfillment location optimization. When a same-day delivery order is placed, the omnichannel warehouse system immediately identifies the closest fulfillment center or store with the necessary stock, ensuring that the order is fulfilled and shipped in the shortest possible timeframe. This process is highly automated, reducing the time and effort required to process same-day delivery orders.

By supporting same-day delivery, the omnichannel warehouse allows businesses to stay competitive in an environment where fast shipping is a key differentiator. Moreover, this fulfillment model enhances customer satisfaction by providing a level of service that meets the increasing demands for speed and convenience.

Flexible and Scalable Storage

The Importance of Adaptable Storage Solutions for Fluctuating Inventory Levels

One of the primary challenges faced by an omnichannel warehouse is managing fluctuating inventory levels across multiple sales channels. In today’s retail environment, demand can change rapidly due to factors such as holiday shopping seasons, promotional events like Black Friday or Cyber Monday, or sudden shifts in consumer preferences. To accommodate these fluctuations, the omnichannel warehouse must be equipped with adaptable storage solutions that allow for the seamless expansion or contraction of storage space.

During peak demand periods, such as the holiday season, an omnichannel warehouse may experience significant increases in order volume. In these situations, traditional static storage solutions can become a bottleneck, leading to inefficiencies such as overcrowded aisles, delayed order picking, or even stockouts. By implementing flexible storage systems, the omnichannel warehouse can quickly adjust its layout to accommodate additional inventory without sacrificing operational efficiency. For example, adjustable shelving systems or mobile storage units can be reconfigured to create more space for high-demand products, allowing for quicker access and faster fulfillment times.

Conversely, when demand decreases, such as during off-peak seasons, the omnichannel warehouse must be able to scale down its storage operations to avoid wasting space and resources. In this scenario, flexible storage solutions allow the warehouse to consolidate inventory into a smaller footprint, reducing overhead costs such as heating, lighting, and labor associated with maintaining unnecessary space. The ability to scale storage space in response to fluctuating demand ensures that the omnichannel warehouse operates efficiently year-round, regardless of market conditions.

In addition to seasonal fluctuations, omnichannel warehouses must also be prepared for demand surges driven by unexpected events, such as viral product trends or supply chain disruptions. By utilizing scalable storage solutions, an omnichannel warehouse can respond quickly to these changes, ensuring that inventory is properly managed and customer orders are fulfilled without delay.

Techniques for Optimizing Warehouse Space

To achieve flexible and scalable storage, an omnichannel warehouse must employ a range of techniques designed to optimize space utilization and accommodate different inventory levels. These techniques not only enhance the warehouse’s ability to scale operations but also improve overall efficiency by ensuring that products are stored and retrieved in the most effective manner possible. Two of the most important techniques for optimizing space in an omnichannel warehouse are the use of dynamic storage layouts and modular systems.

Dynamic Storage Layouts

Dynamic storage layouts are a key strategy for optimizing space in an omnichannel warehouse. Unlike static layouts, where storage locations are fixed and unchanging, dynamic layouts allow for the reconfiguration of storage zones based on current inventory needs. This flexibility is essential in an omnichannel environment, where different products may require different storage solutions depending on factors such as demand, size, and picking frequency.

One common approach to dynamic storage is the use of zone-based storage systems, where the warehouse is divided into different zones that can be adjusted to accommodate various types of products. For example, fast-moving items that are frequently ordered online may be stored in a high-access zone near the packing and shipping areas, while slower-moving products may be placed in a less accessible zone. During peak seasons or promotional periods, the layout can be adjusted to expand the storage capacity of high-demand zones, ensuring that frequently ordered products are easily accessible.

Another technique used in dynamic layouts is slotting optimization, which involves organizing products within the warehouse based on factors such as size, weight, and order frequency. By analyzing historical sales data, the omnichannel warehouse can determine which products are likely to be ordered together and place them in proximity to one another. This reduces the time and effort required for picking and packing, ultimately improving fulfillment speed and efficiency. Slotting optimization also allows the warehouse to reorganize its layout based on changing product demand, ensuring that space is used effectively as inventory levels fluctuate.

Modular Storage Systems

Modular storage systems are another critical component of scalable and flexible storage in an omnichannel warehouse. These systems are designed to be easily reconfigured, allowing the warehouse to quickly adapt to changes in inventory size, product type, or order volume. Modular storage units can be adjusted in height, width, or depth, providing a customizable solution for storing a wide range of products.

One of the most common types of modular storage used in omnichannel warehouses is adjustable shelving. These shelving units can be expanded or contracted to fit different product sizes, ensuring that storage space is maximized without wasting vertical or horizontal space. For example, during a peak season, the warehouse can expand its shelving units to accommodate larger volumes of products, while during off-peak periods, the shelves can be adjusted to store smaller amounts of inventory more efficiently.

Another example of modular storage is the use of mobile racking systems, which allow for the movement of entire storage units to create additional space when needed. These systems operate on tracks or wheels, enabling warehouse workers to move racks as inventory levels change. This flexibility is particularly useful in omnichannel warehouses with fluctuating demand, as it allows for the quick creation of additional storage space without the need for costly renovations or expansions.

Vertical Storage Solutions are also a popular modular system used in omnichannel warehouses, especially those with limited floor space. By utilizing the vertical height of the warehouse, these systems maximize storage capacity without taking up additional square footage. Vertical lift modules (VLMs) and automated storage and retrieval systems (ASRS) are examples of vertical storage solutions that can significantly increase the efficiency of an omnichannel warehouse by automating the storage and retrieval process.

Automated Solutions

The Role of Robotics and Drones in Automating Warehouse Tasks

In an omnichannel warehouse, robotics play a crucial role in automating tasks that would traditionally require significant manual labor, such as picking and packing products for shipment. The implementation of robots in the warehouse can significantly improve both the speed and accuracy of these tasks, allowing the warehouse to keep pace with high volumes of orders, especially during peak periods.

Robotic Picking and Packing

Robotic picking systems are designed to automate the process of selecting items from shelves and preparing them for shipping. In a traditional warehouse, human workers would need to navigate large aisles, manually locate items, and bring them to packing stations. This process can be slow and prone to errors, especially in large warehouses with thousands of products. In contrast, robotic systems in an omnichannel warehouse are capable of locating, retrieving, and delivering products to designated packing stations with remarkable speed and precision.

These robots, often referred to as automated guided vehicles (AGVs) or autonomous mobile robots (AMRs), can be programmed to travel specific routes or navigate the warehouse using advanced sensors and mapping technologies. This automation drastically reduces the time it takes to pick and pack orders, enabling the omnichannel warehouse to fulfill customer orders more quickly. Moreover, robotic systems are able to operate 24/7, allowing warehouses to handle a higher volume of orders without the limitations of human labor, such as fatigue or shift changes.

The omnichannel warehouse also benefits from robotic packing solutions, which automate the process of boxing and labeling items for shipment. This not only speeds up the packing process but also ensures consistent packaging quality, reducing the risk of damaged items during transit. Additionally, robotic packing systems can be integrated with warehouse management software to automatically print and apply shipping labels, further streamlining the process.

Drones for Inventory Checks

In addition to robotics, drones are becoming an increasingly important tool in the omnichannel warehouse, particularly for conducting inventory checks. In a large warehouse, manually counting and verifying inventory can be time-consuming and labor-intensive. Drones equipped with cameras and sensors can fly through the warehouse, scanning inventory in real time and feeding data back to the warehouse management system. This ensures that stock levels are always up to date across all channels, reducing the risk of stockouts or overstocking.

Drones are particularly useful for accessing hard-to-reach areas in the warehouse, such as high shelves or narrow aisles, where manual inventory checks would be difficult or dangerous. By automating this process, the omnichannel warehouse can maintain accurate inventory records without the need for regular physical audits, saving both time and labor costs. The use of drones for inventory management is a key example of how automation is improving operational efficiency in the omnichannel warehouse.

AI-Powered Automation Solutions for Predicting Demand and Optimizing Routes

While robotics and drones automate physical tasks within the omnichannel warehouse, AI-powered systems play a critical role in optimizing the decision-making processes that drive warehouse efficiency. AI-powered automation helps the omnichannel warehouse predict demand, optimize routes for picking and delivery, and manage inventory more effectively.

Predicting Demand with AI

One of the most significant benefits of AI in the omnichannel warehouse is its ability to predict demand with a high degree of accuracy. AI algorithms analyze large datasets from various sources, such as historical sales data, seasonal trends, and even external factors like weather patterns or social media activity. By identifying patterns and trends in this data, AI-powered systems can forecast future demand for specific products, allowing the warehouse to adjust its inventory levels accordingly.

For example, if an AI system predicts a surge in demand for certain products due to an upcoming holiday or promotional event, the omnichannel warehouse can preemptively stock more of those items to ensure they are readily available for fulfillment. This reduces the risk of stockouts and improves customer satisfaction by ensuring that products are always in stock when needed. Additionally, accurate demand forecasting helps the omnichannel warehouse avoid overstocking, which can tie up valuable storage space and increase holding costs.

Optimizing Routes for Picking and Delivery

AI-powered systems also play a crucial role in optimizing the routes used for picking items within the warehouse and delivering orders to customers. In the context of an omnichannel warehouse, where orders may be fulfilled from various locations (such as central distribution centers, local stores, or micro-fulfillment centers), efficient route planning is essential to minimize delivery times and reduce operational costs.

AI systems analyze real-time data to determine the most efficient routes for picking items within the warehouse. For example, if multiple orders contain similar products, the AI system can group these orders together and create an optimized picking route that minimizes travel time between different storage locations. This not only speeds up the picking process but also reduces labor costs by minimizing the distance that workers or robots need to travel within the warehouse.

For last-mile delivery, AI-powered automation systems can optimize delivery routes based on factors such as traffic conditions, weather, and proximity to the customer. By selecting the most efficient routes, the omnichannel warehouse can reduce delivery times and lower fuel costs, all while improving the customer experience by ensuring timely deliveries. This level of optimization is particularly important in an omnichannel environment, where customers expect fast and flexible delivery options such as same-day or next-day shipping.

Enhancing Overall Warehouse Efficiency

In addition to predicting demand and optimizing routes, AI-powered automation enhances the overall efficiency of the omnichannel warehouse by continuously monitoring and analyzing warehouse operations. AI systems can detect inefficiencies in real time, such as bottlenecks in the fulfillment process or underutilized storage space, and suggest corrective actions to improve productivity. For example, if an AI system identifies that certain products are frequently ordered together, it can recommend changes to the warehouse layout to place these products closer to one another, reducing picking times and improving order fulfillment speed.

By automating decision-making processes and providing actionable insights, AI-powered systems enable the omnichannel warehouse to operate more efficiently, reduce operational costs, and improve customer satisfaction.

Multi-location Synchronization

Synchronization of Data Across Multiple Warehouse Locations

In an omnichannel warehouse setup, inventory is distributed across various locations to optimize order fulfillment speed and cost-efficiency. However, to effectively manage this distributed inventory, it is essential to synchronize data across all these warehouse locations. Data synchronization refers to the process of continuously updating and sharing inventory information in real time between different warehouses, retail outlets, and fulfillment centers.

For example, when a customer places an online order, the omnichannel warehouse management system (WMS) must immediately check inventory availability across multiple locations. If the item is available at a nearby warehouse or store, the system can route the order to the closest location for faster fulfillment. This decision-making process relies on real-time data synchronization between all locations to ensure that inventory levels are up-to-date and accurate.

Without proper synchronization, an omnichannel warehouse risks facing challenges such as discrepancies between physical and virtual stock levels. For instance, one warehouse might show items in stock even though they have already been sold through another sales channel, leading to delays in fulfillment and customer dissatisfaction. By maintaining accurate, real-time inventory data across all locations, the omnichannel warehouse ensures that customers receive reliable information about product availability, no matter which sales channel they use.

Moreover, data synchronization plays a critical role in ensuring that the omnichannel warehouse can quickly respond to shifts in demand. For example, during peak shopping seasons or special promotions, certain products may experience a sudden surge in demand. With multi-location synchronization, the omnichannel warehouse can identify which locations have surplus inventory and redistribute stock to areas with higher demand, preventing stockouts and improving overall efficiency.

The synchronization of data across multiple warehouse locations also enables businesses to optimize their order fulfillment strategies. In an omnichannel warehouse, orders can be fulfilled from a variety of locations, such as a central distribution center, a regional warehouse, or even a retail store. By having real-time visibility into inventory levels at each location, the warehouse management system can choose the most efficient fulfillment point, minimizing shipping times and reducing costs.

Ensuring Seamless Coordination Between Various Fulfillment Centers and Retail Outlets

The complexity of an omnichannel warehouse lies not only in managing inventory across multiple locations but also in ensuring seamless coordination between various fulfillment centers and retail outlets. The ability to synchronize operations across these diverse fulfillment points is essential for creating a unified and efficient supply chain. Seamless coordination ensures that all parts of the omnichannel warehouse network work together to meet customer expectations for fast, flexible, and accurate order fulfillment.

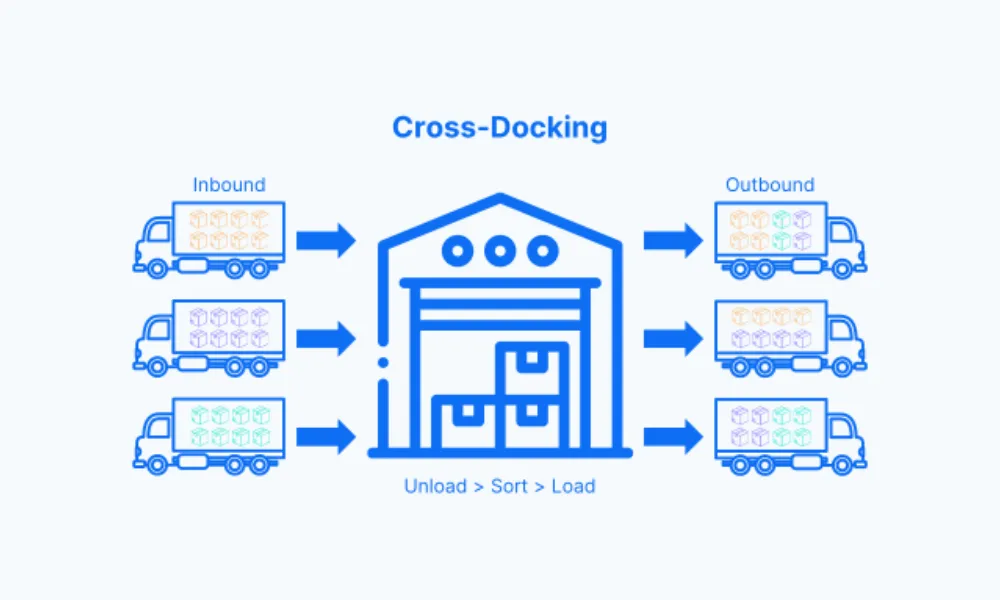

In an omnichannel warehouse, seamless coordination between different fulfillment centers and retail outlets means that the entire network operates as a cohesive system rather than as independent units. For example, if an item is out of stock at a central warehouse but available at a retail store, the omnichannel warehouse system can automatically redirect the order to be fulfilled from the store. Similarly, if a customer chooses to buy online and pick up in-store (BOPIS), the system must synchronize inventory data between the online platform and the store’s inventory system to ensure that the item is available for pickup when the customer arrives.

The coordination between fulfillment centers and retail outlets also extends to managing reverse logistics, which is the process of handling returns. In an omnichannel warehouse, customers may choose to return items to a store, even if they purchased the product online. Seamless coordination ensures that returned items are quickly reintegrated into the inventory system, making them available for resale across all channels. This reduces the time it takes to process returns and restock items, improving overall efficiency and customer satisfaction.

Furthermore, seamless coordination allows the omnichannel warehouse to respond to changes in demand by redistributing inventory across different locations. For example, if a certain product is selling quickly in one region but slowly in another, the omnichannel warehouse system can automatically trigger a stock transfer to balance inventory levels. This level of flexibility is essential for maintaining optimal stock levels and preventing overstocking or understocking at specific locations.

Technology plays a crucial role in ensuring seamless coordination in an omnichannel warehouse. Advanced warehouse management systems (WMS) and enterprise resource planning (ERP) software provide the real-time data synchronization and communication tools necessary to manage inventory and fulfillment operations across multiple locations. These systems integrate data from all sales channels, warehouses, and retail outlets, ensuring that every part of the omnichannel warehouse network is working with accurate, up-to-date information.

Additionally, automated systems and AI-powered tools can help streamline coordination by predicting demand fluctuations, optimizing stock levels, and suggesting the most efficient fulfillment strategies. These technologies enable the omnichannel warehouse to respond quickly to changes in demand, ensuring that customers receive their orders on time, regardless of the fulfillment location.

Challenges in Managing an Omnichannel Warehouse

Inventory Management

Managing Multi-channel Inventory

One of the greatest challenges of managing an omnichannel warehouse is handling inventory across multiple sales channels. In a traditional warehouse, inventory might be stored in one central location and used to fulfill orders for a specific sales channel, such as a physical store or an eCommerce platform. In an omnichannel warehouse, however, inventory must be distributed and managed across a range of locations, including physical stores, regional distribution centers, and even external marketplaces like Amazon or eBay. Each of these channels has different requirements for inventory management, fulfillment, and customer service, making it essential to have a unified system in place that can handle the complexity of multi-channel operations.

In an omnichannel warehouse, it is crucial to have real-time visibility into inventory levels across all channels. This means that whether a customer is shopping online, in-store, or through a mobile app, they should always have access to accurate product availability information. Without this real-time visibility, businesses risk overselling items that are no longer in stock or missing out on sales because products are incorrectly listed as unavailable. This can lead to customer dissatisfaction and lost revenue.

To effectively manage multi-channel inventory, businesses must implement advanced warehouse management systems (WMS) that allow for centralized inventory control and real-time updates across all sales platforms. These systems integrate with various sales channels, ensuring that inventory is synchronized and accurately reflected across the entire omnichannel network. When an order is placed, the system updates stock levels in real time, regardless of where the inventory is stored or where the order was placed. This integration helps eliminate discrepancies between sales channels, reduces the risk of errors, and enables businesses to fulfill orders quickly and accurately.

Moreover, managing multi-channel inventory in an omnichannel warehouse requires sophisticated logistics and fulfillment strategies. For instance, businesses must determine how best to allocate inventory across different locations to ensure that orders can be fulfilled as quickly and cost-effectively as possible. This might involve shipping products from a central warehouse, fulfilling orders from a local store, or using a combination of fulfillment centers depending on customer location and inventory availability. Balancing these logistics is essential for optimizing both inventory levels and fulfillment speed in an omnichannel warehouse environment.

Avoiding Stockouts and Overstocking

Stockouts occur when an item is unavailable at the time of purchase, causing missed sales opportunities and customer frustration. Overstocking, on the other hand, occurs when too much inventory is held in the warehouse, tying up capital and consuming valuable storage space. Both scenarios can have a detrimental impact on business operations, profitability, and customer satisfaction.

Avoiding Stockouts

Stockouts are particularly damaging in an omnichannel warehouse because they affect not only one sales channel but the entire network. If a customer is unable to find a product online, in-store, or on a third-party platform, the business risks losing that sale to a competitor. In addition, stockouts can lead to delays in order fulfillment, especially if inventory needs to be transferred from one location to another to fulfill an order. To avoid stockouts, businesses must have real-time visibility into inventory levels and the ability to anticipate demand accurately across all channels.

Demand forecasting plays a critical role in preventing stockouts. In an omnichannel warehouse, demand forecasting involves analyzing historical sales data, customer behavior, and market trends to predict future demand for products across various channels. By forecasting demand accurately, businesses can ensure that the right amount of inventory is available in each location to meet customer needs without running out of stock. For example, if a particular product is known to sell well during certain seasons or promotional periods, the omnichannel warehouse can preemptively stock more of that item to avoid stockouts during peak demand.

Another strategy for avoiding stockouts is maintaining safety stock, which serves as a buffer to protect against unexpected demand spikes or supply chain disruptions. In an omnichannel warehouse, safety stock can be distributed across various locations to ensure that even if one warehouse runs low on a particular item, other locations can step in to fulfill orders. This decentralized approach to inventory management helps minimize the risk of stockouts and ensures that customer orders can be fulfilled on time, even during high-demand periods.

Avoiding Overstocking

While stockouts can lead to lost sales, overstocking can result in financial losses by tying up capital in excess inventory and increasing storage costs. Overstocking is especially problematic in an omnichannel warehouse because the inventory is spread across multiple locations, making it more difficult to track and manage effectively. Excess inventory can also lead to markdowns and discounts, which erode profit margins and reduce the overall profitability of the business.

To avoid overstocking, businesses must balance inventory levels with actual demand. This requires careful planning and the use of data analytics to monitor sales trends and adjust inventory levels accordingly. In an omnichannel warehouse, it is important to avoid holding too much inventory in one location while other locations remain understocked. By distributing inventory more evenly across the omnichannel network, businesses can reduce the risk of overstocking in any single location and ensure that products are available where they are most likely to sell.

Advanced inventory management systems can help businesses avoid overstocking by automating the process of reordering and replenishing inventory based on real-time data. For example, if inventory levels in one location are higher than expected, the system can automatically adjust future orders to prevent overstocking. Similarly, if a product is selling more slowly than anticipated, the system can reduce the amount of stock ordered for that location in the next replenishment cycle. This level of automation and data-driven decision-making helps optimize inventory levels across the omnichannel warehouse and minimizes the risk of overstocking.

Balancing Inventory Across Channels

To successfully avoid stockouts and overstocking, businesses must focus on balancing inventory levels across all sales channels and fulfillment locations. This involves distributing inventory based on demand forecasts, sales patterns, and customer behavior across online platforms, physical stores, and other channels. By strategically positioning inventory across the omnichannel warehouse network, businesses can ensure that stock levels are optimized for each location and that customer orders can be fulfilled quickly and accurately.

Inventory management is a critical challenge for any omnichannel warehouse. Managing multi-channel inventory requires real-time visibility and centralized control to ensure that inventory levels are accurate and consistent across all locations. Avoiding stockouts and overstocking is essential for maintaining smooth operations, minimizing costs, and meeting customer expectations. By using advanced technology and data-driven strategies, businesses can effectively manage inventory in an omnichannel warehouse and achieve the right balance between supply and demand.

Complexity in Order Fulfillment

Balancing Cost and Speed

One of the most significant challenges faced by omnichannel warehouses is balancing the cost of order fulfillment with the speed at which customers expect their orders to arrive. Consumers are increasingly accustomed to fast or even same-day delivery, especially as eCommerce giants like Amazon set new benchmarks for fulfillment speed. However, meeting these expectations can be costly, particularly for businesses that do not have the infrastructure to support rapid delivery across multiple locations.

In an omnichannel warehouse, order fulfillment costs can vary greatly depending on the strategy employed. For instance, ship-from-store is a popular fulfillment method where orders placed online are fulfilled from a nearby retail location rather than a central warehouse. This strategy can reduce delivery times, as items are shipped from the closest store to the customer’s location, which also helps reduce shipping costs. However, while ship-from-store can improve delivery speed, it can be more expensive to operate in the long run, as retail stores may not be optimized for efficient picking, packing, and shipping like a dedicated warehouse.

Another fulfillment strategy used in omnichannel warehouses is direct-to-consumer shipping from a central warehouse or distribution center. This model allows businesses to leverage their warehouse infrastructure to manage inventory, process orders, and ship directly to customers. While this method is more cost-effective than ship-from-store in terms of operational efficiency, it may not be as fast, particularly if the warehouse is located far from the customer. This creates a tension between cost and speed that businesses must navigate when selecting the most appropriate fulfillment strategy for their omnichannel warehouse.

To balance cost and speed effectively, many businesses adopt a hybrid fulfillment approach in their omnichannel warehouse. This strategy involves using multiple fulfillment methods depending on the proximity of inventory to the customer, the urgency of the delivery, and the associated costs. For instance, a business might use ship-from-store for local, high-priority orders, while relying on direct-to-consumer shipping for orders that are less time-sensitive or for customers located farther away from retail locations.

Optimizing fulfillment strategies in an omnichannel warehouse requires real-time visibility into inventory levels across all locations. This visibility allows businesses to choose the most cost-effective and timely fulfillment option for each order. Advanced warehouse management systems (WMS) and AI-driven automation tools can analyze factors such as product availability, customer location, and shipping costs to determine the optimal fulfillment strategy for each order, reducing both costs and delivery times.

Handling Reverse Logistics

Another key challenge in managing an omnichannel warehouse is efficiently handling reverse logistics, which involves processing returns, exchanges, and refunds. With the growth of eCommerce, customers have become accustomed to flexible return policies and the ability to return products purchased online to physical stores or through mail-in options. While these options enhance the customer experience, they significantly complicate the operations of an omnichannel warehouse.

In an omnichannel warehouse, reverse logistics is more complex than in a traditional warehouse environment due to the multiple sales and return points involved. Customers may purchase an item online and return it to a store, or they may purchase an item in-store and initiate a return through a different online platform. Managing these diverse return scenarios requires a seamless integration of systems that can track and process returns from all channels while ensuring that inventory is updated accordingly.

One of the main challenges in reverse logistics for omnichannel warehouses is the cost associated with processing returns. Returns involve multiple touchpoints, including inspection, repackaging, restocking, and sometimes refurbishing. This process can be labor-intensive and costly, especially if the product needs to be shipped back to a central warehouse from a retail store or customer’s home. To mitigate these costs, omnichannel warehouses must implement efficient return processing systems that streamline the flow of returned goods and minimize the time products spend in the reverse logistics loop.

Inventory management is also a critical aspect of handling reverse logistics in an omnichannel warehouse. When a product is returned, it needs to be quickly reintegrated into the inventory system so that it can be resold. This requires real-time updates across all sales channels to ensure that the returned item is available for purchase as soon as it is restocked. Failing to do so can result in lost sales opportunities or excess stock sitting idle in the warehouse.

To manage reverse logistics more effectively, many omnichannel warehouses leverage automated return systems. These systems use AI and machine learning algorithms to streamline the return process by categorizing returned products, determining whether they can be resold, and automatically updating inventory systems. Automated systems can also help reduce the time it takes to process refunds or exchanges, improving customer satisfaction and reducing the operational burden on the warehouse.

Additionally, the omnichannel warehouse must ensure that the return policies are consistent across all channels. Whether a customer is returning a product in-store or by mail, the process should be straightforward, and the same level of service should be provided. This consistency enhances the customer experience and strengthens brand loyalty, but it requires seamless coordination between the warehouse, retail outlets, and online platforms.

Data Integration and Synchronization

Maintaining Real-time Data Synchronization

One of the key challenges of managing an omnichannel warehouse is maintaining real-time data synchronization across all connected systems. With multiple sales channels, warehouses, and fulfillment centers involved, the need for accurate and up-to-date data is paramount. Real-time synchronization ensures that all inventory, sales, and customer data are aligned, regardless of whether the transaction happens in-store, online, or through a third-party marketplace.

In an omnichannel warehouse, real-time synchronization allows businesses to track and manage inventory levels across all channels, preventing stock discrepancies and ensuring that orders are fulfilled accurately and on time. For instance, when a customer places an order online, the warehouse management system must immediately update the stock levels across all platforms—eCommerce websites, in-store point-of-sale systems, and third-party sellers—to reflect the new inventory status. This real-time update helps prevent the problem of overselling, where customers may be able to purchase items that are no longer available due to a lag in data updates.

Moreover, real-time synchronization helps optimize the order fulfillment process by ensuring that orders are directed to the most appropriate warehouse or fulfillment center based on current inventory levels. For example, if a customer orders a product online and it is available at a nearby store, real-time data synchronization enables the system to route the order to that location for faster fulfillment through a ship-from-store model. Without real-time data, this type of dynamic decision-making would not be possible, and businesses risk delays, inefficiencies, and unhappy customers.

In addition to inventory management, real-time data synchronization also impacts customer experience. Customers expect accurate and up-to-date information on product availability, delivery times, and order status. With real-time synchronization between systems, businesses can provide customers with real-time order tracking, ensuring that they are kept informed about the status of their purchase. This transparency builds trust and enhances customer satisfaction, which is especially important in an omnichannel retail environment.

To achieve real-time data synchronization, businesses must invest in integrated technology solutions that connect their warehouse management system (WMS), enterprise resource planning (ERP) system, and eCommerce platforms. These systems must be able to communicate and share data in real-time, providing a unified view of inventory, sales, and customer interactions. Additionally, advanced technologies such as cloud-based platforms and the Internet of Things (IoT) can play a key role in facilitating real-time data updates across an omnichannel warehouse.

Integration Challenges

While real-time data synchronization is essential for the smooth operation of an omnichannel warehouse, integrating legacy systems with new omnichannel technologies presents a significant challenge for many businesses. Legacy systems are often outdated, rigid, and lack the flexibility needed to handle the complexities of an omnichannel environment. These older systems were not designed to support the integration required for modern omnichannel operations, leading to data inconsistencies, delays in processing, and even system failures.

One of the primary difficulties in integrating legacy systems with modern omnichannel technologies is the lack of compatibility between different platforms. For example, a legacy warehouse management system may not be able to communicate effectively with a new eCommerce platform or ERP system, resulting in a disjointed flow of data. This lack of integration can cause serious problems, such as delayed order processing, inaccurate inventory levels, and misaligned sales data. When inventory, sales, and customer data are not properly integrated, it becomes difficult to maintain a consistent and accurate view of the business across all sales channels.

Another major challenge businesses face when integrating legacy systems into an omnichannel warehouse is the high cost and complexity of the integration process. Many legacy systems were built on outdated technology frameworks, making it difficult to connect them with modern cloud-based platforms or advanced data analytics tools. As a result, businesses must often invest significant time and resources into custom development, middleware solutions, or third-party integration services to bridge the gap between legacy systems and new omnichannel technologies.

Data migration is another hurdle businesses must overcome during the integration process. Legacy systems often contain large volumes of historical data, such as customer information, sales records, and inventory details, which must be transferred to the new omnichannel platforms. Ensuring that this data is accurately migrated without any loss or corruption is critical, as incomplete or inaccurate data can lead to operational inefficiencies and poor decision-making in the omnichannel warehouse. Moreover, data migration must be conducted in a way that minimizes disruption to the ongoing operations of the warehouse, making it a complex and time-sensitive task.

The lack of real-time capabilities in many legacy systems also poses a significant challenge. Traditional systems may rely on batch processing or periodic updates, which means that inventory and sales data may not be updated in real-time. In an omnichannel warehouse, where orders and inventory levels are constantly changing across multiple platforms, these delays can result in stock discrepancies, overselling, or understocking. To address this issue, businesses must either upgrade their legacy systems to support real-time data processing or replace them with modern, cloud-based systems that are designed for omnichannel operations.

To overcome these integration challenges, many businesses are turning to cloud-based solutions that provide greater flexibility, scalability, and real-time data synchronization capabilities. Cloud-based platforms enable seamless integration between different systems, allowing businesses to connect their WMS, ERP, and eCommerce platforms in real-time. Additionally, cloud-based systems can be easily updated and expanded to accommodate new sales channels, making them ideal for the dynamic nature of omnichannel warehouses.

Businesses must also adopt a phased approach to integration, gradually replacing or upgrading legacy systems over time while ensuring that critical operations are not disrupted. By prioritizing the integration of key systems, such as inventory management and order fulfillment, businesses can begin to experience the benefits of real-time data synchronization while minimizing the risk of costly system failures.

Demand Fluctuations

Handling Seasonal Peaks

Seasonal peaks, such as the holiday shopping season, Black Friday, and back-to-school periods, are some of the most challenging times for an omnichannel warehouse. These peak seasons can see a massive increase in order volumes across all sales channels, placing enormous strain on inventory levels, order processing times, and shipping logistics. Customers expect fast delivery and seamless service during these high-demand periods, so any delays or stock shortages can lead to dissatisfied customers, lost sales, and damage to the brand’s reputation.

In an omnichannel warehouse, managing seasonal peaks requires careful planning and preparation well in advance. One of the key strategies is forecasting demand based on historical data from previous peak seasons, sales trends, and market analysis. By analyzing this data, businesses can better predict which products will be in high demand and ensure that they have sufficient stock to meet customer needs. However, forecasting alone is not enough. The omnichannel warehouse must also implement a flexible inventory management system that allows it to scale operations quickly in response to changing demand patterns.

Another strategy for handling seasonal peaks in an omnichannel warehouse is inventory distribution across multiple locations. Instead of relying on a central warehouse to fulfill all orders, businesses can spread inventory across regional warehouses, fulfillment centers, and even retail stores. This approach reduces the risk of stock shortages in any one location and helps expedite delivery times by ensuring that products are closer to customers. For example, a business might use a ship-from-store model to fulfill online orders during peak seasons, leveraging the inventory in physical stores to reduce the strain on central warehouses.

Automating warehouse operations is another critical aspect of managing seasonal demand surges. Automation technologies, such as robotics, conveyor systems, and automated picking tools, can significantly improve the speed and accuracy of order fulfillment. By automating repetitive tasks like picking, packing, and sorting, the omnichannel warehouse can handle larger volumes of orders without requiring a proportional increase in labor. This is particularly important during seasonal peaks when hiring and training temporary workers may not be feasible or cost-effective.

In addition to automation, flexible staffing models can help businesses handle increased demand during peak seasons. Many omnichannel warehouses use temporary or seasonal workers to supplement their regular workforce during high-demand periods. However, the key to success lies in having an efficient training program that enables temporary workers to quickly adapt to the warehouse’s processes and technologies. Some warehouses also use flexible shift scheduling to ensure that they have enough labor during the busiest times of the day, while avoiding overstaffing during slower periods.

Despite careful planning and preparation, bottlenecks can still occur during seasonal peaks. To mitigate these risks, omnichannel warehouses should implement contingency plans that address potential challenges such as supplier delays, transportation issues, or equipment failures. For instance, having backup suppliers or alternative shipping routes can prevent disruptions in the supply chain and ensure that customer orders are fulfilled on time, even when unexpected challenges arise.

Managing Flash Sales and Unexpected Demand

Flash sales, promotional events, and viral marketing campaigns can lead to sudden and dramatic spikes in demand that are difficult to predict. These events often generate excitement among customers, resulting in a flood of orders within a short time frame. For an omnichannel warehouse, handling these sudden surges in demand can be extremely challenging, as they put pressure on both inventory levels and fulfillment systems. If not managed effectively, flash sales can lead to stock shortages, delayed shipments, and customer dissatisfaction.

To successfully manage flash sales and unexpected demand surges, omnichannel warehouses must be agile and responsive. One of the most important strategies is real-time inventory tracking. Real-time visibility into inventory levels across all sales channels ensures that businesses can quickly identify when stock is running low and take corrective action. For example, if a product becomes a bestseller during a flash sale, the warehouse management system can automatically adjust inventory levels, trigger reorders, and reallocate stock from other locations to prevent stockouts.

Another key to managing flash sales in an omnichannel warehouse is dynamic order prioritization. During periods of high demand, not all orders are equally urgent. By using real-time data and predictive analytics, the warehouse can prioritize orders based on factors such as customer location, shipping speed, and product availability. For instance, orders for high-demand items that are in limited supply might be fulfilled from multiple locations to ensure fast delivery, while less urgent orders can be processed later. This approach helps balance the workload and prevents the fulfillment system from becoming overwhelmed.

Scalability is another critical component of managing unexpected demand surges in an omnichannel warehouse. Scalability refers to the ability of the warehouse to quickly expand its operations to meet higher demand without sacrificing efficiency. Cloud-based warehouse management systems (WMS) and enterprise resource planning (ERP) platforms enable businesses to scale their operations by providing real-time data, automation tools, and seamless integration across sales channels. These systems can automatically adjust fulfillment processes, allocate resources, and update inventory data in real time, allowing the warehouse to handle sudden spikes in demand with minimal disruption.

In addition to scalable technology solutions, omnichannel warehouses can implement just-in-time inventory practices to manage unexpected demand surges. Just-in-time inventory management involves keeping minimal stock on hand and relying on frequent replenishment to meet demand. While this strategy carries some risks, such as potential delays from suppliers, it can be effective in managing flash sales by ensuring that inventory is constantly replenished without the need for excessive stockpiling. By working closely with suppliers and maintaining strong communication channels, the omnichannel warehouse can respond quickly to demand fluctuations and keep inventory levels aligned with customer orders.

Finally, effective communication with customers is essential when managing flash sales and unexpected demand surges in an omnichannel warehouse. Customers need to be informed about product availability, estimated delivery times, and any potential delays due to high order volumes. Transparency in communication helps set realistic expectations and reduces the likelihood of negative feedback or order cancellations. Automated notification systems can be used to keep customers updated on the status of their orders, while customer service teams can provide real-time support for any questions or concerns.

Labor Shortages and Skills Gaps

Addressing Workforce Shortages

Labor shortages have become a significant challenge for omnichannel warehouses, especially during periods of high demand such as holiday seasons, Black Friday, or flash sales. The shortage of skilled warehouse workers can lead to delays in order fulfillment, increased operational costs, and ultimately, a decline in customer satisfaction. As omnichannel warehouses continue to expand their operations to meet the demands of multi-channel retail, the need for a reliable and scalable workforce becomes increasingly critical.

One of the primary causes of labor shortages in omnichannel warehouses is the fluctuating nature of demand. During peak seasons, warehouses often experience a sharp increase in order volumes, requiring a larger workforce to handle the surge in activity. However, hiring and training temporary workers to manage these short-term spikes in demand can be costly and inefficient. In addition, the demand for warehouse workers often outpaces supply, making it difficult for businesses to find and retain skilled employees when they need them most.

To address these workforce shortages, omnichannel warehouses are increasingly turning to automation and robotics to fill the gaps. By automating repetitive tasks such as picking, packing, and sorting, warehouses can reduce their reliance on manual labor and improve efficiency. Automated guided vehicles (AGVs), robotic picking systems, and conveyor belts are just a few examples of how automation can help omnichannel warehouses cope with labor shortages. While automation may not entirely replace the need for human workers, it can significantly reduce the burden on the workforce during peak demand periods and help ensure that orders are fulfilled on time.

Another strategy for addressing labor shortages in omnichannel warehouses is the use of temporary or seasonal workers. Many warehouses hire additional staff during busy periods to handle the increased workload. However, to be effective, this approach requires efficient training programs that can quickly onboard temporary workers and get them up to speed on warehouse processes and technologies. Cross-training permanent employees in multiple roles can also help alleviate workforce shortages by providing more flexibility in staffing. For example, employees trained in both order picking and packing can be shifted between roles as needed, allowing the warehouse to adapt to changing demands more efficiently.

Partnerships with staffing agencies can also be an effective way to address workforce shortages. Staffing agencies can provide omnichannel warehouses with access to a pool of pre-screened and trained workers who can be deployed quickly during peak demand periods. This can save time and resources, as the warehouse does not need to handle the recruitment and training process internally. In addition, working with staffing agencies can provide greater flexibility in scaling the workforce up or down based on real-time demand fluctuations.

Training and Retaining Skilled Workers

While automation can alleviate some of the pressure caused by labor shortages, there is still a strong need for skilled workers who can manage, operate, and maintain the technology that powers an omnichannel warehouse. The increasing reliance on automation, robotics, and warehouse management software (WMS) means that warehouse employees must possess a higher level of technical knowledge than ever before. However, the rapid pace of technological advancement often leaves warehouses facing a skills gap, where employees may not have the necessary training to use these systems effectively.

One of the most important strategies for addressing skills gaps in an omnichannel warehouse is to implement comprehensive training programs that upskill the workforce in new technologies and processes. These training programs should focus on teaching employees how to operate and troubleshoot automation systems, use WMS effectively, and optimize warehouse workflows. For example, workers should be trained on how to manage automated picking systems, monitor real-time inventory data, and utilize data analytics tools to improve operational efficiency. By equipping employees with the skills they need to work with advanced technology, omnichannel warehouses can improve productivity and reduce the likelihood of errors or delays in the fulfillment process.

Training programs should also emphasize cross-functional skills to increase workforce flexibility. In an omnichannel warehouse, employees may be required to perform multiple tasks, such as managing inventory, picking and packing orders, and operating machinery. By cross-training employees in different roles, warehouses can ensure that their workforce is adaptable and capable of shifting between tasks as needed. This flexibility is particularly valuable during peak demand periods when certain areas of the warehouse may require more resources than others.

In addition to upskilling the workforce, retaining skilled employees is critical for the long-term success of an omnichannel warehouse. High employee turnover can lead to increased recruitment and training costs, as well as disruptions in operations. To reduce turnover, warehouses must focus on creating a positive work environment, offering competitive wages, and providing opportunities for career growth and advancement.

One of the most effective ways to retain skilled workers in an omnichannel warehouse is to invest in employee development programs. These programs can provide workers with ongoing training and development opportunities, helping them to build their skills and advance their careers within the company. By offering opportunities for professional growth, warehouses can increase employee engagement and job satisfaction, making it less likely that workers will seek employment elsewhere. For example, employees who show an interest in technology can be offered additional training in warehouse automation systems or given the chance to take on leadership roles in managing new technologies.

Employee recognition and reward programs can also play a key role in improving retention. Recognizing and rewarding employees for their hard work, particularly during peak demand periods, can boost morale and encourage loyalty. This can be as simple as offering bonuses or incentives for meeting performance targets or providing recognition through employee of the month programs. Creating a culture of appreciation helps employees feel valued and motivates them to stay with the company.

Finally, offering flexible work schedules can help omnichannel warehouses attract and retain skilled workers, particularly during peak demand periods. Many workers, especially those in the gig economy, value flexibility in their work schedules. By offering options such as part-time shifts, flexible hours, or remote work for administrative roles, warehouses can appeal to a broader pool of workers and improve employee satisfaction.

Strategies for Implementing Omnichannel Warehousing

Assessing Business Needs

Identifying Current Pain Points

Before transitioning to an omnichannel warehouse, it is important to evaluate the inefficiencies and challenges within existing warehouse operations. Many businesses experience pain points related to stockouts, slow fulfillment times, or difficulties in integrating inventory and sales data across multiple sales channels. These issues not only impact operational efficiency but also affect customer satisfaction, as delays in fulfillment or inaccurate stock levels can lead to lost sales and frustrated customers.

One of the most common pain points in traditional warehouse operations is inventory management, particularly in managing stock across multiple sales channels. Businesses that rely on separate systems for online orders, in-store purchases, and third-party marketplaces often struggle to keep track of inventory in real time. As a result, they may face stockouts in one channel while carrying excess inventory in another. This leads to inefficiencies, such as missed sales opportunities due to unavailable products or increased holding costs for overstocked items. Implementing an omnichannel warehouse allows for centralized inventory management, ensuring that stock levels are synchronized across all channels and that products are allocated more efficiently to meet demand.

Another significant pain point is slow fulfillment caused by inefficient warehouse processes. Traditional warehouses may not be optimized to handle the high volume of orders generated by eCommerce platforms or the fast fulfillment speeds demanded by modern customers. For instance, a warehouse designed to serve brick-and-mortar stores may not have the systems in place to manage online orders efficiently. By transitioning to an omnichannel warehouse, businesses can streamline fulfillment processes, such as by implementing ship-from-store or click-and-collect options that reduce shipping times and improve customer satisfaction.

In addition to inventory and fulfillment challenges, businesses often face integration issues when managing multiple sales channels. For example, legacy systems used to manage physical store inventory may not integrate well with eCommerce platforms or third-party marketplaces, leading to data discrepancies and delays in updating stock levels. This lack of integration creates confusion for both the warehouse and the customer, as products may be shown as available online when they are actually out of stock. Implementing an omnichannel warehouse involves integrating these systems to ensure that inventory data is consistent and updated in real time, regardless of the sales channel.

By identifying these pain points, businesses can better understand where omnichannel warehouse strategies can make the greatest impact. Whether it’s improving inventory management, speeding up fulfillment, or integrating sales platforms, omnichannel warehousing offers solutions to common operational challenges.

Understanding Customer Expectations

A successful omnichannel warehouse strategy must also be built around a deep understanding of customer expectations. In today’s competitive retail environment, customers expect more from businesses, including faster shipping, real-time access to product availability, and flexible fulfillment options such as buy online, pick up in-store (BOPIS). Failing to meet these expectations can lead to lost customers, negative reviews, and damage to a brand’s reputation. Therefore, businesses must align their warehouse processes with customer preferences to deliver a seamless and satisfying shopping experience.