Are you looking to improve your inventory management process? If so, you may be wondering what is inventory analysis? Understandably so – after all, effective inventory management is vital to success in any business.

Inventory analysis is a technique used by marketers and developers to track, measure, and optimize the stock of products or services. By understanding what inventory items are selling well and which ones aren’t, retailers and businesses can make the best data-driven decision.

In this blog post, we will define inventory analysis, explore some common techniques and KPIs, and discuss how you can use inventory analysis to improve your business’s bottom line. Let’s get started!

Table of Contents

What is Inventory Analysis?

Inventory analysis is the practice of identifying and cataloging the items in a company’s stock. This can be done manually or through automated means. The goal of inventory analysis is to get an accurate picture of what a company has on hand so that they can make informed decisions about ordering and stocking levels.

There are several different techniques that can be used for inventory analysis, and the key performance indicators (KPIs) that you choose to track will depend on your specific needs and goals. One of the most important KPIs for Inventory Analysis is the Inventory Turnover Ratio. This measures how efficiently a company is using its Inventory to generate sales. Other KPIs could include Days of Inventory on Hand and Inventory Costs as a Percentage of Sales.

Benefits of inventory analysis

Inventory Analysis is a valuable tool for businesses of all sizes. Inventory analysis can help improve your organization’s cash flow, delight customers with better pricing, and reduce inventory waste. By reducing stockouts and project delays, inventory analysis can also help improve your organization’s overall efficiency.

Additionally, inventory analysis also can help you get the best prices from suppliers and vendors. By understanding your organization’s inventory needs and trends, you can make more informed decisions about where to allocate your resources. This can lead to improved profitability for your business.

Inventory analysis is a valuable tool for any organization looking to improve its operations and performance. For example, Wal-Mart increased its Inventory Turnover Ratio from 3.5 to 6.2 by using inventory analysis techniques. And Coca Cola was able to reduce its Inventory Costs as a Percentage of Sales from 30% to 15%.

Techniques for inventory management

There is a variety of Inventory Management Techniques that companies can use in order to ensure they have the right amount of stock on hand and are not paying for too much or too little inventory. Below are some common Inventory Management Techniques.

- Just-in-Time Inventory Management is a popular Technique for companies that want to reduce the amount of inventory they hold. This approach involves ordering products only when they are needed, which helps to reduce storage costs and improve cash flow. However, it can be difficult to implement and may not be suitable for all products.

- Dropshipping is a Technique that allows companies to sell products without having to carry any inventory. When a customer places an order, the company will contact the supplier, who will then ship the product directly to the customer. This eliminates the need for the company to invest in stock, and can be a useful tool for expanding their product range.

- Cross-docking is another Inventory Management Technique that can help companies save time and money. This approach involves receiving products from suppliers and shipping them directly to customers, without storing them in between. This helps to reduce the amount of time products spend in transit, and can be a useful tool for companies that sell products online.

- Consignment Inventory is a Technique that allows companies to store products at the supplier’s warehouse until they are sold. This can be helpful for companies that want to avoid the cost of storage, and can help to improve cash flow by reducing the amount of time it takes for products to be sold. However, it can be difficult to track inventory levels using this approach.

- ABC analysis: ABC analysis classifies inventory into three categories: A, B, and C. Items in category A are considered the most important and should be given the highest priority when it comes to stock levels and order quantities. Items in category B are less important than those in category A, and items in category C are the least important.

Choosing the right Inventory Management Technique is important for ensuring that your company has the right amount of stock on hand while avoiding the cost of over or under-stocking. By understanding the different Inventory Management Techniques available, you can make an informed decision about which one is right for your business.

Key Inventory Analysis Metrics

When it comes to inventory, there are a few key metrics you need to be aware of in order to make sure your business is running as smoothly as possible. Let’s take a look at each of these metrics and what they mean for your business.

- GMROI (Gross Margin Return on Inventory) measures the effectiveness of your inventory management by indicating how much profit is generated from each dollar invested in inventory. This metric is especially important for businesses that carry a large amount of inventory, as it can help you determine whether or not that investment is profitable.

- CSL (Conversion Selling Level) measures the average number of products sold per customer visit. This metric can help you to determine how much inventory you need to keep on hand in order to meet customer demand.

- ATP (Available to Promise) measures the amount of stock you have available to sell at any given time. This metric can be helpful in preventing stockouts and ensuring that you always have enough product on hand to meet customer demand.

- Inventory Turnover Rate indicates how often your Inventory is sold and replaced over a period of time. This metric can help you to determine whether or not you need to stock more or less inventory in order to maintain a desired level of sales.

- Stockout Rate measures the percentage of time that you do not have any product available for sale. A high stockout rate can be very costly for a business, as it can lead to lost sales and customers.

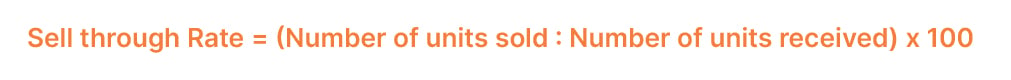

- Sell-Through Rate measures the percentage of products that are sold as compared to the amount of products that are offered for sale. This metric can help you to determine whether or not you are offering the right product mix to your customers.

- Back Order Rate measures the percentage of time that orders are placed but not filled due to a lack of inventory. A high back order rate can be very costly for a business, as it can lead to lost sales and customers. By understanding these key metrics, you can take steps to improve your inventory management and ensure that your business is running as smoothly as possible.

Example of Successful Company using inventory analysis techniques

Apple

Apple is a company that is known for its innovative products and cutting-edge technology. However, what many people don’t know is that behind the scenes, Apple has a very efficient Inventory Management system in place. The company uses an Inventory Analysis tool to track stock levels and forecast future demand. This helps them to ensure that they always have enough stock on hand, while also avoiding overstocking. As a result, Apple has been able to maintain a high level of customer satisfaction while keeping its inventory costs low.

Toyota

Toyota is another company that is well-known for its efficient Inventory Management. The automaker uses a variety of tools, such as Kanban cards and inventory forecasting software, to track stock levels and plan production. This allows Toyota to ensure that they always have the right amount of parts on hand, while also minimizing waste. As a result, Toyota has been able to maintain a high level of quality while keeping its inventory costs low.

Glossier

Glossier is a cosmetics company that is known for its high-quality products and trendy designs. The company has achieved this by using an Inventory Management system that is based on demand forecasting. Glossier forecasts demand for each product and then produce only the amount that is needed. This system has allowed Glossier to keep its inventory costs low, while still offering a large selection of products.

IKEA

IKEA is a furniture retailer that is known for its low prices and stylish designs. The company has achieved this by using an Inventory Management system that is based on just-in-time (JIT) inventory principles. JIT Inventory relies on having a very small amount of inventory on hand so that goods are only ordered and produced when they are needed. This system has allowed IKEA to keep its inventory costs low, while still offering a large selection of products.

How to Start using Inventory Analysis in your Business?

An inventory audit is the first step in using inventory analysis. This is when you review all of your stock and determine how much you have, what it’s worth, and how it’s being used. Inventory management software can help make this process easier by tracking stock levels and usage trends.

Inventory management software is an essential tool for any business looking to improve its inventory analysis. By using them, you can make sure that your stock levels are always in line with what you need, minimizing waste and maximizing profits

In fact, Odoo is one of the most effective inventory management tools available. A wide range of capabilities is available for handling various business tasks such as eCommerce management, customer relationship management (CRM), point of sale (POS), supply chain management, and inventory management. Furthermore, It is possible to handle and track numerous delivery orders, dropshipping orders, receptions, and requests for inventory items with the help of Odoo ERP inventory management software ERP. Additional shipping providers such as UPS, DHL, FedEx, and even local post offices are supported by the specialized modules as well. The use of this function makes the process of managing shipping operations much simpler and more convenient.

Final thoughts on Inventory Analysis

Inventory analysis is a critical component of effective supply chain management. By understanding your inventory position and trends, you can identify opportunities for growth and improvement in your business operations.

Moreover, If you are searching for an Odoo ERP implementation, Magenest can provide you with all allied services in Odoo, including customization, implementation, support, and maintenance for future requirements. We have been an Odoo silver partner for several years and have a wide range of experience in assisting customers in the development of inventory management systems. If you have any questions, you can contact our professionals to find out more about how service can help you achieve success.